- Joined

- Jun 12, 2014

- Messages

- 5,153

I have yet to see a machine manufacture at this price level specify an oil of a particular manufacturer as the only one you can use, so lets get realistic about this as it applies to this level of machinery. These machines are shipped all over the world, I highly doubt that they all have access to Mobil DTE XYZ, or whatever brand. They specify the type and the ISO, they often will give a particular brand as an example of that era. Many of the "recommended oils" no longer exist. Unless you read something in the warranty that gives a specific statement that the warranty is VOID if you use anything else and you need to show proof, etc. then it isn't enforceable, and even then it may depend on the state you live in. You might have very specific specifications if you have a Rolls Royce turbine engine, but a lathe or mill, I don't think so.

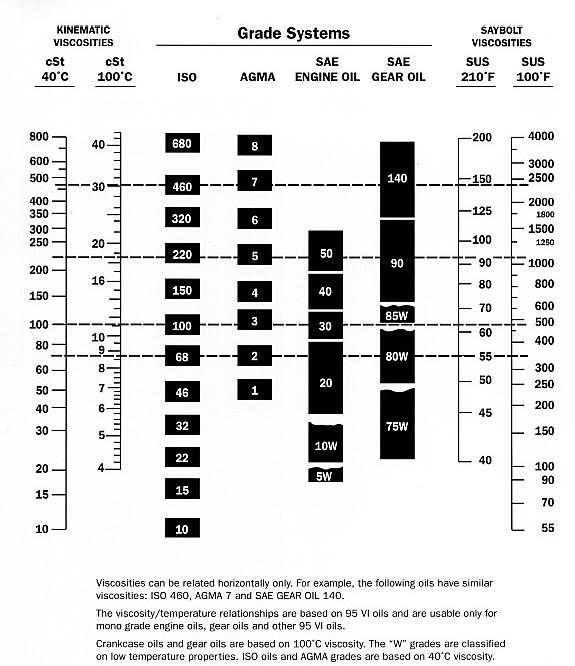

It is well understood that there are equivalent oils between brands, and they will have comparable performance. We are talking basic oil here, and nothing fancy, people are lead to believe there is a huge difference between the oils, between most name brand this is not the case. The biggest cause of failure from lack of lubrication is not the oil brand but operator negligence from not changing the oil, wrong quantity, or using something totally out of specifications. You will see lots of people saying motor oil is fine for their lathe, etc. but the biggest issue with splash lubrication is the wrong viscosity at the designed operating temperature and speed/type of the gears. With splash lubrication, too thin an oil does not have the film thickness, too high a viscosity and the oil will not flow through the channels to the bearings and you get heat generation due to the higher viscosity.

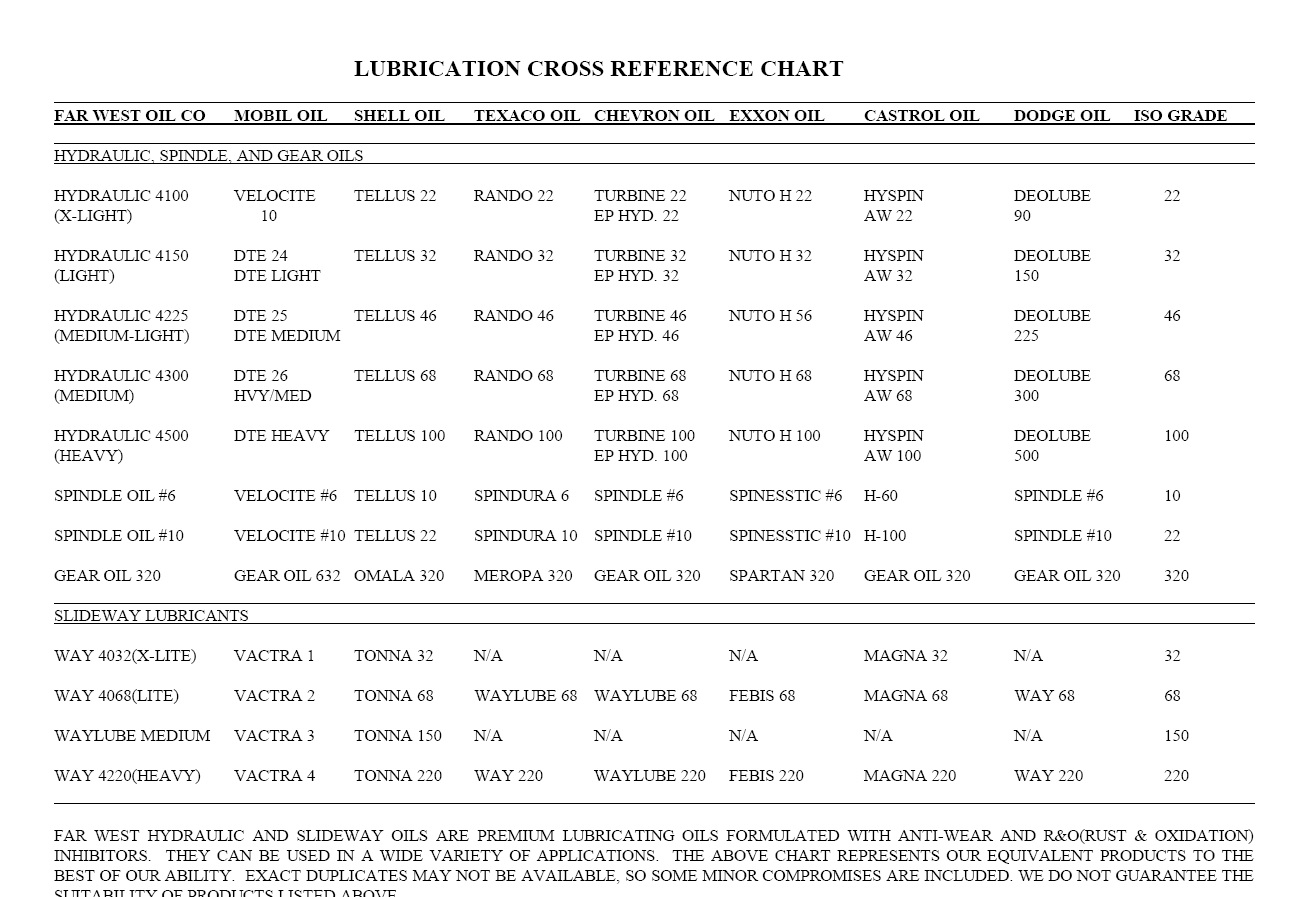

Below is an older oil equivalence chart, if you speak to oil distributors which I have on a number of occasions they will give you comparable products between the different brands. They are equivalent. The QMT manuals specifically say's "ISO XX, such as Mobil ...", Grizzly lists their own oils or equivalent, I cannot recall any lathe or mill manual that indicates only a particular brand can be used.

So go with the indication/oil type and the ISO grade, the brand is your choice. Would I runout and get K-Mart hydraulic oil in the automotive department, probably not. I have followed these discussions on oils for years, have had discussions with oil techs from companies for specific indications, at this level it is not rocket science. Buy a decent brand oil, change the oil regularly. If you are that unsure about if XYZ oil is OK ask the manufacturer. In a commercial setting where machines operate 24/7 and trying to minimize down time, then slight difference between oils might be a factor based on factual evidence that a difference exsits.

It is well understood that there are equivalent oils between brands, and they will have comparable performance. We are talking basic oil here, and nothing fancy, people are lead to believe there is a huge difference between the oils, between most name brand this is not the case. The biggest cause of failure from lack of lubrication is not the oil brand but operator negligence from not changing the oil, wrong quantity, or using something totally out of specifications. You will see lots of people saying motor oil is fine for their lathe, etc. but the biggest issue with splash lubrication is the wrong viscosity at the designed operating temperature and speed/type of the gears. With splash lubrication, too thin an oil does not have the film thickness, too high a viscosity and the oil will not flow through the channels to the bearings and you get heat generation due to the higher viscosity.

Below is an older oil equivalence chart, if you speak to oil distributors which I have on a number of occasions they will give you comparable products between the different brands. They are equivalent. The QMT manuals specifically say's "ISO XX, such as Mobil ...", Grizzly lists their own oils or equivalent, I cannot recall any lathe or mill manual that indicates only a particular brand can be used.

So go with the indication/oil type and the ISO grade, the brand is your choice. Would I runout and get K-Mart hydraulic oil in the automotive department, probably not. I have followed these discussions on oils for years, have had discussions with oil techs from companies for specific indications, at this level it is not rocket science. Buy a decent brand oil, change the oil regularly. If you are that unsure about if XYZ oil is OK ask the manufacturer. In a commercial setting where machines operate 24/7 and trying to minimize down time, then slight difference between oils might be a factor based on factual evidence that a difference exsits.

Last edited: