- Joined

- May 3, 2020

- Messages

- 189

Thank you for the insight. The QR code on the box isn't quite scannable so I have requested a better image of it from them, as well as pictures showing any high spot markings.I honestly don't know what the radial bearing is doing, so I'm not sure if it would make a difference or not.

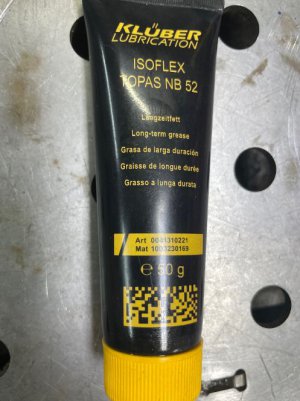

I used to work in the bearing industry, they estimate 10% of the bearings sold worldwide are counterfeit, so I avoid buying bearings on Ebay or other non-authorized distributors. The first bearing you show is selling for 10% of the normal price, that is a huge red flag for me. You can go to this website and scan the bar code of the bearing box of the second listing and it will let you know what that bar code belongs to and if it matches what is on the bearing. https://www.stopfakebearings.com/ Look and see if there is high spot markings on the bearings, I know NSK does that on their precision bearings, so if that is missing, then it should be a hard pass. You might not be able to see it in the pictures, maybe you could get the sell to get you better pictures.

Concerning the price on the first bearing, I would normally be inclined to agree, but the seller appears to be a reputable industrial surplus dealer. The first picture of the listing shows a very weathered looking box and an inspection certificate bearing a 1990 date. It's also the only one they are selling unlike many dubious operations on eBay that sell these things en masse at suspiciously low cost. Could it be a counterfeit? I guess anything is possible, but it would be a lot of work to make all this up to sell one bearing for $40. It could have been a counterfeit back then too I suppose.

I'm a little more dubious of the NSK bearings considering that they are in new appearing packaging. Definitely would like to scan the QR and scrutinize them more closely. The seller only has two available and has been on eBay since 2001 with positive feedback, but that doesn't mean that they aren't unknowingly selling a fake.