Thanks Jim!

Since it seems like Mach 4 is up and running, I am switching gears back to the hardware side of this build.

First off, I got the matching buttons for my operator button station. I have labels for each of these. They are the Allen Bradley 800FP series of operators (22mm). The plastic ones, while plenty sturdy, feel a little cheap. There are metal versions of these but I couldn't find any cheaply on ebay. The back side of the button is modular to select which contacts you want as well as lamps if the button is illuminated. Top hole is for an ESTOP which is temporarily setup elsewhere.

Edit: I guess cheap feeling is relative. They are super nice compared to most operators you get from automation direct or hobby grade stuff, but are a long shot from the mil-spec buttons and knobs I work with day to day.

Thanks to the folding mount, the computer tucks neatly behind the machine for cleaning. The mount is already getting bent, so I am looking for something a little more sturdy.

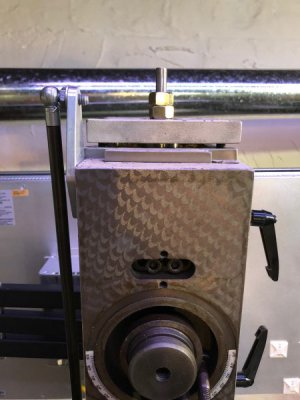

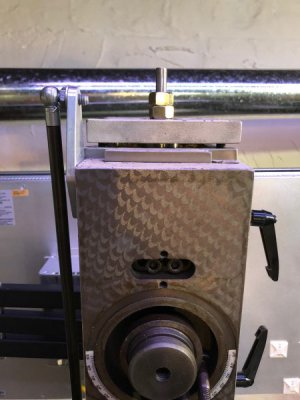

Loosening 4 bolts removes the top bearing plate from the Z axis.

From there the 50lb gas strut can be disconnected.

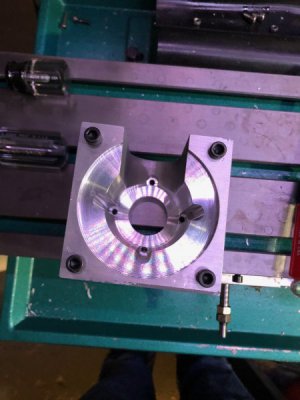

The gib can be knocked loose. Note that all sides are flat (no milled pockets). The way facing side is ground and flaked, the opposite side is just ground. The spare gib just looks rough machined, not ground or flaked. That being said these things bend like a noodle so I'm not sure how much value comes from grinding.

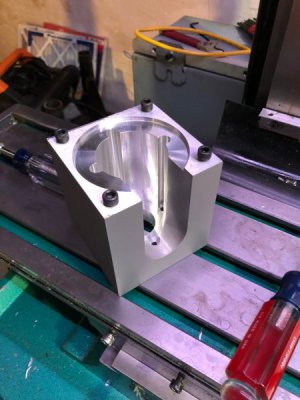

And the Z axis slide completely removed.

The way cover is completely shot and I got a replacement from Grizzly for $22.

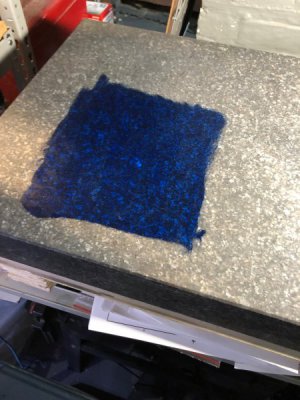

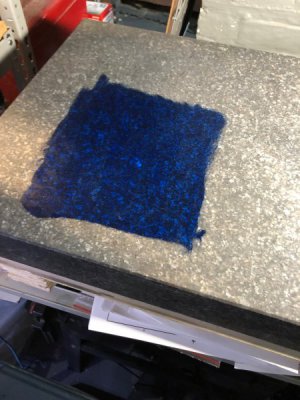

I used some Dykem Hi-Spot blue to see how bad the gib was (hint: terrible). I don't have a great way to spread the ink so I use a tightly balled paper towel. I feel like half the ink sticks to the towel, but a tube is cheap.

I covered the edge which was rubbing on the flat way with steel blue and ground it on my bench grinder until the ink was cleaned up. I was fairly conservative with material removal so I may need to take a few more passes later on. Dummy here didn't cover the surface plate with a sheet so all the exhaust and grinding dust landed on the Hi-spot blue and stuck. I can be a little dense sometimes. I will completely cover the plate in the future.

The first spotting of the gib shows very little contact. I was able to bend it a little straighter by hand and get better contact along the length. I ground the end of a file with a slight rake and a wide radius and used it as a make shift scraper. I'm sure it doesn't work anywhere near as well as a real one, but I'm able to remove a touch of material. I'm not trying to scrape this into perfection (nor am I really sure how), but I'd like to get a touch more contact than it has. This is my first attempt at any kind of scraping.

Question: I've seen Sandvik, Biax, and Anderson scrapers for sale but they are large and fairly expensive. Are there any smaller sub-$100 scrapers for things like gibs and touchups that you could recommend. Maybe one day I'll take the leap and get all the scraping essentials, but for now having something to do some touchup would be great.

After a little file scraping and stoning I am getting better contact (not shown by the blue currently, I already wiped half of it off). This is the replacement Z axis gib. Note that it comes in very long and is a cut-to-length kind of deal.