- Joined

- Mar 26, 2018

- Messages

- 2,725

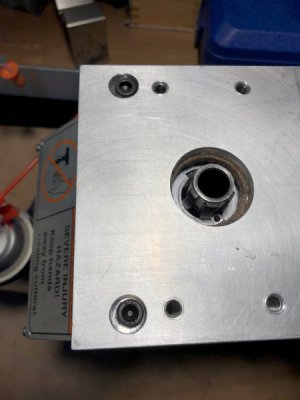

Got some new bolts in the mail and got the spindle assembled. Unfortunately, working just from a CAD model bit me again and not all of the mounting holes on the top of the spindle line up (guess the Chinese factories put holes wherever they please). I'm hoping I can open up the counterbored holes on my aluminum mount to get things positioned better. Of course now I don't have a mill to use so I'll have to butcher it on the drill press...

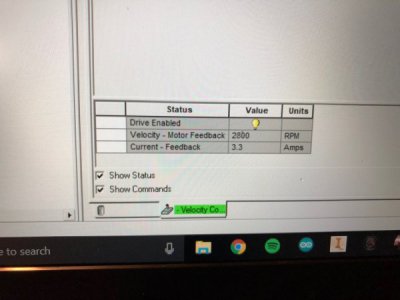

I was able to get the motor and belt mounted on 3 out of the 4 screws and got it up and running. I am slowly breaking in the bearings/belt and taking detailed measurements of torque consumption, temperature, and noise as I work up in speed. I'll post those results when I'm done testing, but I can say right now that it is a LOT quieter. At 1500rpm it measures about 10dBA less that my lathe running at 550rpm with no gears engaged. The lathe is quite comfortable to run without earplugs.

I have only run it up to 1500rpm so far, but the highest bearing temp was 89 degrees in a 72 degree ambient temp (I'm right next to the furnace).

All in all it seems to be going well, stay tuned for test results.

I was able to get the motor and belt mounted on 3 out of the 4 screws and got it up and running. I am slowly breaking in the bearings/belt and taking detailed measurements of torque consumption, temperature, and noise as I work up in speed. I'll post those results when I'm done testing, but I can say right now that it is a LOT quieter. At 1500rpm it measures about 10dBA less that my lathe running at 550rpm with no gears engaged. The lathe is quite comfortable to run without earplugs.

I have only run it up to 1500rpm so far, but the highest bearing temp was 89 degrees in a 72 degree ambient temp (I'm right next to the furnace).

All in all it seems to be going well, stay tuned for test results.