- Joined

- Jun 12, 2014

- Messages

- 5,127

ER collets for the most part should have stock/end mills through the full length of the collet to prevent it from distorting when clamped. It is hard to hold short stock in an ER collet, and also if passing bolts through the collet ER collets they tend to be too long for smaller hardware. With a 5C collet I have held stock as short as 0.1" in depth, and also use it frequently for holding threaded items. I use 5C collets primarily, and reserve my ER collets on the lathe for metric/odd size stock. Due to the short clamping range of 5C collets, a 1/64th increment set is often required to hold a full range of stock. This is adds the expense vs. an ER collet set.

I use a speed handle for my 5C chuck which makes for quicker collet changes, there is also speed chucks as well as a 5C drawbar which would be quicker than using an ER collet chuck. I primarily use my ER collets for end mills on the mill and tailstock of the lathe.

5C one can screw in a stop system to the back of the collet, but they are not repeatable for accurate work vs. a through the spindle stop system that can be used with either type of collet system. My ER lathe chuck does have a rear screw in stop system.

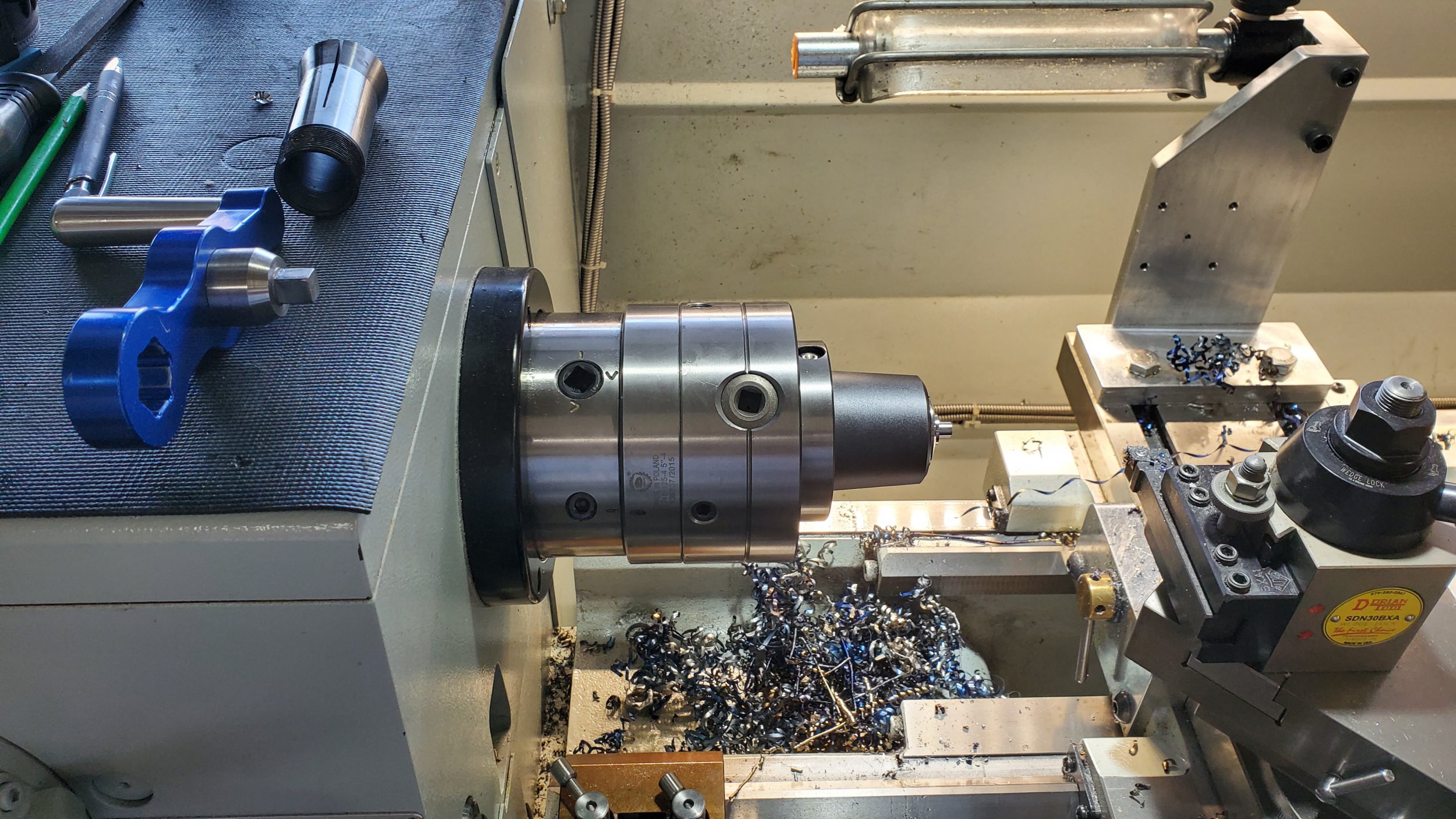

5C collet holding small part, 0.2" depth is being held by the collet.

I use a speed handle for my 5C chuck which makes for quicker collet changes, there is also speed chucks as well as a 5C drawbar which would be quicker than using an ER collet chuck. I primarily use my ER collets for end mills on the mill and tailstock of the lathe.

5C one can screw in a stop system to the back of the collet, but they are not repeatable for accurate work vs. a through the spindle stop system that can be used with either type of collet system. My ER lathe chuck does have a rear screw in stop system.

5C collet holding small part, 0.2" depth is being held by the collet.