I just purchased a used 1500W BLDC spindle motor and control board from a VM32 mill, that I plan to use to replace the factory 1HP brushed motor on my 10x22 lathe.

This "upgrade" appears to offer several advantages:

1) The original 1HP brushed motor lacks low speed torque, so the extra ~1HP should help out

2) I'm setting this up to be CNC capable and the original brushed motor accomplishes direction reversal by hard switching the 90V, 10A switching via the F/R switch. Hard switching the polarity to the motor for CNC will require a pretty hefty relay, (DC current doesn't like to be switched). The BLDC controller appears to be able to be reversed with low power control signals, and that will simplify the required CNC interface.

3) The original motor runs at half speed (which is often slower than desirable) when in reverse, they do this to preserve the brushes when running in reverse. So no more brushes, no more reduced speed in reverse.

4) Brushed motors require brush maintenance, so hopefully the BLDC motor will be more reliable in the long term.

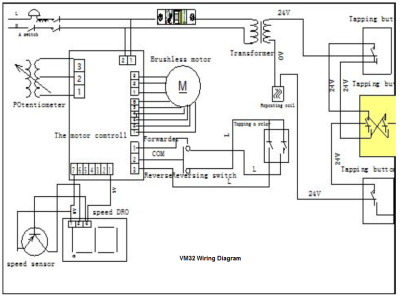

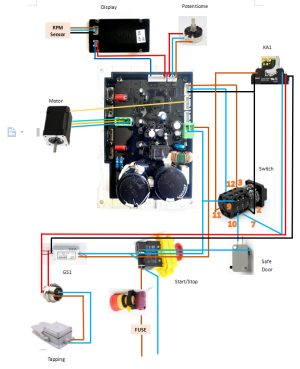

The wiring diagram in the VM32 manual is a bit "sketchy" on the details it's more of a conceptual diagram than a schematic. So I'm going to need to figure out and make an accurate wiring diagram.

The good news I think, is that Weiss sells an optional foot pedal switch that appears to allow forward/reverse action on the fly, I think the intent is for tapping. None of this is explained in the manual, and Weiss has not responded to my emails requesting details. I can't decipher the lousy wiring diagram with any certainty, however my best guess is that pressing the foot switch causes the spindle to turn forward and releasing it causes the spindle to reverse, so I guess the foot switch has some sort of toggle action, but I'm not sure.

Plan is to exploit that foot switch interface.

So if anyone has this option please explain how it works.

Much appreciated

I have attached the sketchy wiring diagrams that I found, as well as video showing the foot switch in action.

This "upgrade" appears to offer several advantages:

1) The original 1HP brushed motor lacks low speed torque, so the extra ~1HP should help out

2) I'm setting this up to be CNC capable and the original brushed motor accomplishes direction reversal by hard switching the 90V, 10A switching via the F/R switch. Hard switching the polarity to the motor for CNC will require a pretty hefty relay, (DC current doesn't like to be switched). The BLDC controller appears to be able to be reversed with low power control signals, and that will simplify the required CNC interface.

3) The original motor runs at half speed (which is often slower than desirable) when in reverse, they do this to preserve the brushes when running in reverse. So no more brushes, no more reduced speed in reverse.

4) Brushed motors require brush maintenance, so hopefully the BLDC motor will be more reliable in the long term.

The wiring diagram in the VM32 manual is a bit "sketchy" on the details it's more of a conceptual diagram than a schematic. So I'm going to need to figure out and make an accurate wiring diagram.

The good news I think, is that Weiss sells an optional foot pedal switch that appears to allow forward/reverse action on the fly, I think the intent is for tapping. None of this is explained in the manual, and Weiss has not responded to my emails requesting details. I can't decipher the lousy wiring diagram with any certainty, however my best guess is that pressing the foot switch causes the spindle to turn forward and releasing it causes the spindle to reverse, so I guess the foot switch has some sort of toggle action, but I'm not sure.

Plan is to exploit that foot switch interface.

So if anyone has this option please explain how it works.

Much appreciated

I have attached the sketchy wiring diagrams that I found, as well as video showing the foot switch in action.

Attachments

Last edited: