- Joined

- Aug 2, 2020

- Messages

- 691

I think he is looking at a very good sized machine and I would not go smaller.Quite often, I see absolute novices looking at purchasing large lathes and I wonder why.

A large lathe is more expensive to purchase and to run. Tooling is more expensive. If you are grinding your own HSS tools, it takes a lot more work to grind a 5/8" tool than a 1/4" tool. Power requirements quickly exceed that available in most hobby workshops. A large lathe is more of a hazard to personal safety and property if/when something goes wrong. Novices are more prone to make mistakes that a seasoned machinist would avoid. Large lathes take up considerably more space than their smaller counterparts. Large lathes typically require engaging the services of a rigger at some considerable additional expense and shipping costs also tend to be expensive.

Very few lathe projects exceed a 3" x3" work envelope, more so for a novice machinist. There have been numerous examples of exquisite work accomplished on lathes with swings smaller than 12" and travel less than 30". Very few are turning truck axles or flywheels for heavy equipment.

My suggestion is start with a smaller lathe. Gain some experience using it . If/when you feel that you need or want a larger machine, sell the starter and get the larger machine then.

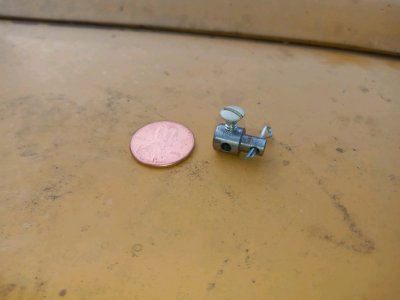

Here are two projects I've done on my 14 1/2 X 30 lathe. The little one could have been done on almost any lathe.

The square end on the part I'm boring is

10 1/2" corner to corner.

You aren't going to do that job on a lathe much smaller.

@Coenbro -

I think it is not worth the extra $ to upsize to a bigger lathe just to have it three phase.

Single phase is just fine for us hobbiests who aren't running real big machines.

My old lathe was 3 phase when I bought it so I needed to do something in order to run it.

And once I built the RPC and got over that common stumbling block, that opened my eyes to watching for other three phase machines and my collection (and capabilities) grew.