- Joined

- Sep 13, 2018

- Messages

- 282

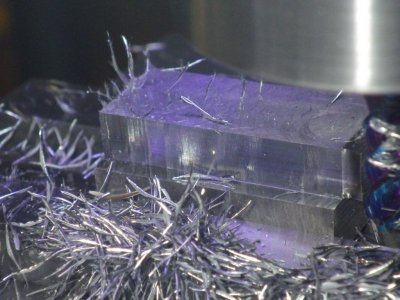

Roughing seems to imply heavy cuts?

I buy these 4flute, 5, 6 and 8mm end mills from https://www.aliexpress.com/item/1005003464938830.html and other suppliers there. I have found no reason to use anything bigger even on larger parts. Esp. the 6mm I can run at 2000rpm at quite a high feed rate even in steel making up for any disadvantage from less cut width.

Gerrit

I buy these 4flute, 5, 6 and 8mm end mills from https://www.aliexpress.com/item/1005003464938830.html and other suppliers there. I have found no reason to use anything bigger even on larger parts. Esp. the 6mm I can run at 2000rpm at quite a high feed rate even in steel making up for any disadvantage from less cut width.

Gerrit