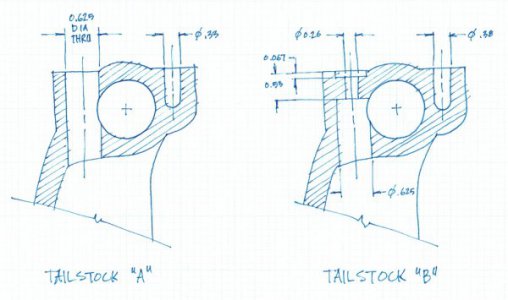

14. I cleaned the tailstock hole and all the pieces with Simple Green, a red Scotchbrite pad and a round brush and filed the burrs off and got the sleeves to fit without getting stuck. However, there are 2 different tail stocks. I pulled the locking assembly off the one on the bottom, but my lathe tailstock is shown on top. The hole is smaller on mine than the old one so I cannot stack the sleeves in the hole (it's a bigger diameter from the underside). They have the same part number on the castings. The parts diagram I have for my lathe shows a tailstock like the bottom one:

I can either have just one sleeve, switch tailstocks, or shorten the sleeves. Thoughts?

I can either have just one sleeve, switch tailstocks, or shorten the sleeves. Thoughts? I found some extra sleeves with my lathe that are the same length as the ones shown. My tailstock is in better condition cosmetically, but they both appear to be functional.

Here is the locking assembly showing the sleeves:

15-16. Noted. I used machine oil after cleaning these with Simple Green and a rag.

17. The Phillips heads would not budge. I sprayed penetrating oil on them a few days ago, too. I was able to get the carriage off as follows:

-Unscrew the leadscrew bearing bolts (the ones holding it to the bed on the right side) and remove the nut and washer on the end.

-I removed the bolt holding the leadscrew drive gear on the left.

-I gently tapped the bearing and the whole leadscrew came off. I discovered this by accident when I was trying to get just the bearing off. I wasn't able to get just the bearing off the leadscrew. It was probably better this way anyway since I would have had to support the leadscrew at one end.

This allowed me to slide off the carriage.