- Joined

- Dec 25, 2011

- Messages

- 10,552

Jeff,

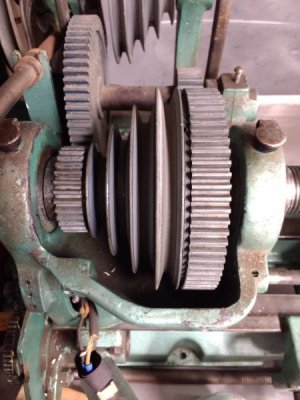

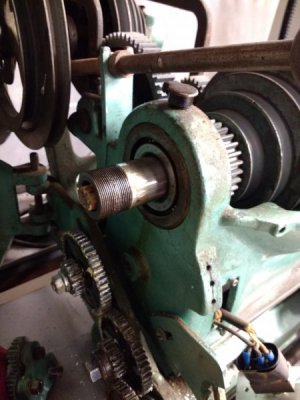

I hate to say this, but RTFM. Both the exploded view parts list and the Atlas Technical Bulletin on the 10" headstock show a Woodruff key in the spindle to keep the gear from turning on the spindle. Plus, if you have the collar off, you should be able to see that the gear has a keyway either cast or broached in it. Make an aluminum or brass protector for the left end of the spindle by turning a piece of solid round of 1-1/4" or larger diameter down to 3/4" by about 1/2". Slide that into the left end of the spindle and hit it with a dead blow hammer or a steel hammer and a piece of 2 by 4.

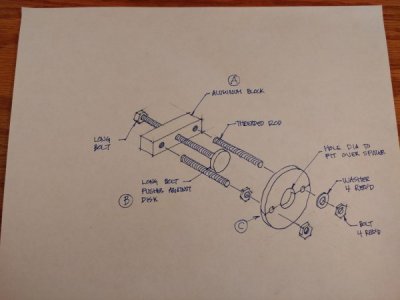

Or make a receiver for the right side of the headstock out of structural tubing with an ID just larger than the dust cover. Make a thrust shoulder washer of 1/2" steel plate with about a 25/32" ID and an OD about the same diameter as the tubing. Run a length of 3/4" all thread through the shoulder washer, receiver, and spindle and put a flat washer and long nut on both ends. Loosen the set screw in the bull gear, and tighten the nuts.

I hate to say this, but RTFM. Both the exploded view parts list and the Atlas Technical Bulletin on the 10" headstock show a Woodruff key in the spindle to keep the gear from turning on the spindle. Plus, if you have the collar off, you should be able to see that the gear has a keyway either cast or broached in it. Make an aluminum or brass protector for the left end of the spindle by turning a piece of solid round of 1-1/4" or larger diameter down to 3/4" by about 1/2". Slide that into the left end of the spindle and hit it with a dead blow hammer or a steel hammer and a piece of 2 by 4.

Or make a receiver for the right side of the headstock out of structural tubing with an ID just larger than the dust cover. Make a thrust shoulder washer of 1/2" steel plate with about a 25/32" ID and an OD about the same diameter as the tubing. Run a length of 3/4" all thread through the shoulder washer, receiver, and spindle and put a flat washer and long nut on both ends. Loosen the set screw in the bull gear, and tighten the nuts.