I like your choice and also have what I feel are one of these generic vises that are popular because of the price. They mate well but I found they do not hold evenly under load. Lock up on a Parallel to make sure they hold the work correctly / squarely. Had to shim the stationary jaw to get it to hold correctly.

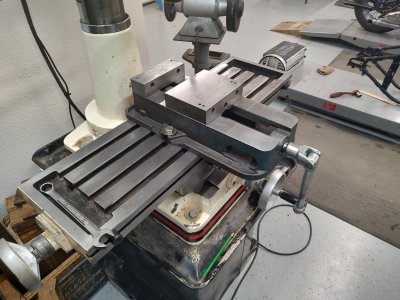

I recently picked up a Vevor 4" vice.

I had previously managed to pick up a couple of 6" Abwood vices and one 4" Abwood vice (got all three for a song from Charter Auctions in the UK. It seems that the other bidders were put off by a bit of grime and some worn paint; they're all smooth as you like and nary a bit of movement of the workpiece at the moment the vices are tightened) and found that even the 4" caused me restriction with Y axis movement (mind you, my table's only 8 x 26") because of the design.

So I took a look at some YouTube 'reviews', wasn't entirely convinced by them but thought it's worth a punt at that price and bought it.

When it arrived, I stripped it down, cleaned it good (there was a fair bit of dirt under the jaw faces) and put it back together again noting that the counterbored clearance holes for the SHCS in the jaw faces were probably a little more generous than they should be.

I checked the squareness and parallelism of the faces, and I found that providing the surfaces behind and below the jaw faces were clean and the SHCS were screwed in carefully and tight, all was good.

I've checked jaw lift with a tenths DTI, and there's virtually none; most I've seen is between 1 and 2 tenths. Guess Vevor ripped off that accu-lock (or whatever it's called) real good!

Maybe I've been lucky but for the price, I reckon mine's a pretty good vice.

All the above said, if someone can afford (either or both the money and space on their table) a vice from a more reputable manufacturer; I reckon used or new would be a better idea. If I had a deeper table, I'd not be selling the Abwood vices I think.