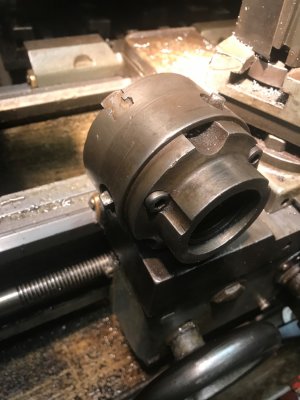

My mini-lathe spindle plate has holes for both 3 and 4 bolts. If yours has only 3 you have a couple options, either make or buy an adapter plate, or modify the lathe spindle plate to have 4 holes. The last option, in my opinion has more chances to mess up, so I'd recommend the first.

Using your lathe you can make such an adapter. When I started out I would forget that I had the capabilities to make things at a level far beyond my pre-lathe days. Unlearning helplessness is hard. We can make stuff, given the will and desire.

That being said, sometimes it's far cheaper to modify existing parts to get to the end. If you can find a disk of steel you can make an adapter plate from it. It need not be cast iron. Or modify something from Little Machine Shop.

There's few rules in machining, whatever gets you to the finish line is all that matters. You don't have to do things the optimal way, just a way that gets you to where you need. Making stuff is how you learn, making mistakes teaches both what not to do and what works. Learning from others often helps us make fewer mistakes.