- Joined

- Apr 23, 2018

- Messages

- 7,055

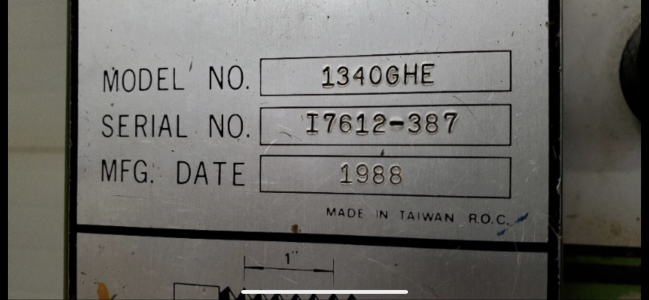

Yes, that looks reasonable. My 1760 uses ISO 68 as one oil to rule them all. If a manufacturer specs ISO 32 for the headstock, it's probably because of the bearings and clearances they used. Victor (TW) makes an honest product, I expect Victor lathes to have a lube schedule data plate on them. I'm pretty sure someone here has a Victor 1440 lathe as their primary home shop workhorse. I'm not sure if you're talking about the new Victor lathes that look like PM clones, or the cool older Victors that look like rugged Takisawa derivatives. I'm sure you can find a manual or lube schedule for one of the major clones out there.