- Joined

- Aug 6, 2015

- Messages

- 3,887

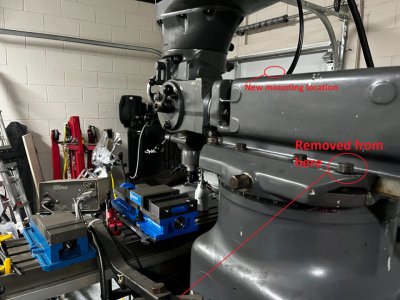

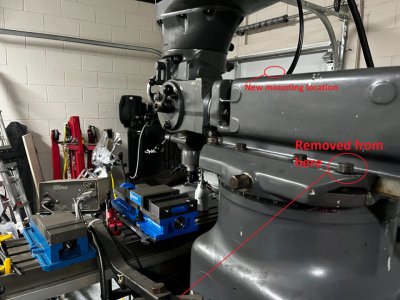

Aso removed the arm that holds the DRO display. I did not like how it was mounted. Previous owner attached it to one of the bolts that hold down the gib.

I need to buy a washer as the one there is gone.

My plan is to flip the arm around and install it from the top. There is hole there, big hole that will require some large washers. Either that or drill and tap a hole to secure it.

Doing all this for two reasons. (1) I really do not think that the arm should have been secured from that bolt and (2) I need it to be more sturdy so that I can install the VFD control box on the bottom of the DRO Display. So everything is within reach, but also able to swing away if needed.

I need to buy a washer as the one there is gone.

My plan is to flip the arm around and install it from the top. There is hole there, big hole that will require some large washers. Either that or drill and tap a hole to secure it.

Doing all this for two reasons. (1) I really do not think that the arm should have been secured from that bolt and (2) I need it to be more sturdy so that I can install the VFD control box on the bottom of the DRO Display. So everything is within reach, but also able to swing away if needed.

Last edited: