Much to do before I can say that I am done with all the things needed to be finished, but I had to make that first cut!! Using just a block of aluminum... Cutting tool is an Accusize Indexable End Mill with 3 carbide inserts and a 2" cutting diameter.

Funny thing is that at first, with all the excitement of making that first cut...I was scratching my head as to why it was not working... I had it with the belt in the lowest setting on the pulley... the spindle was spinning but it would stop as soon as I moved it to the material and started cutting... I was just beyond myself.... thinking I had wasted all this money on this machine and it did not work!!

Hard headed newbie, what am I to do... give it more speed of course (MORE POWER!!)... I switched it all off, moved the belt to a higher setting... Ah, there! Now it will work... Turn on the VFD... and now the spindle would not spin one bit... Motor was spinning faster... spindle was not moving...

Long story longer... I forgot to put the machine in gear

. Switched it to gear... First chips made... Life is good.

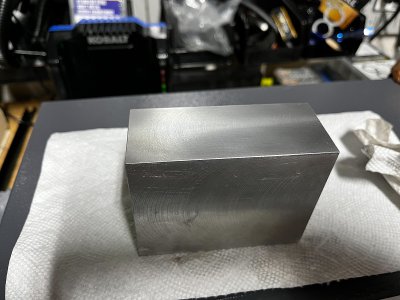

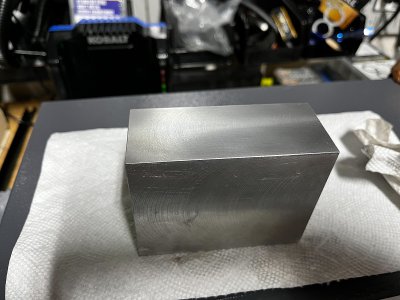

Already scratched the surface with the caliper... Oh, and I only did that top surface... side cut you see there was old... I wanted to cut all sides, but forgot parallel bars at the other house...

Anyway, interesting how it looks in the photo... surface is smooth to the touch...

Video of the first chips made!!!! Wohoooo!!!