-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wells-Index 847 Milling Machine - Ownership Thread

- Thread starter wachuko

- Start date

- Joined

- Aug 6, 2015

- Messages

- 3,887

Updating the list...

Pending

Pending

- Cleaning... lots of cleaning needed. In progress.

- Shaft on Z axis seems to be bent. Need to check how much this part and order a replacement.. plus I need to figure out if this can be replaced without having to take apart the table... if it can be done with minimal disassembly

- Lowering quill takes more effort than normal. Need to take apart that area to inspect what is causing the issue.

- Pending install of Z-axis stops

- Order and install an updated DRO setup. Mine has no functions. Wonder if I can reuse the scales and avoid having to install new ones...or if these are too old to be compatible with newer DRO displays

- First priority is to decide on what VFD to buy. I was made aware that a static converter is less expensive, but reading on those, they could heat up the motor, power comes down... I do not mind spending a little bit more on a VFD if that works better than a static unit... Just need to figure out which one. If I do decide to try the static converter, @matthewsx mentioned having good experience with those from North America Phase Converters

- Add a remote control box for VFD

- Clean DRO display box. Apply labels for X and Y. Relocate bracket/arm.

- Repair oil lines - Oil system completely overhauled

- Power draw bar. Being tall must have been a requirement for working in a machine shop. I need something to avoid having to use a ladder to get to the drawbar!! I have seen different setups. Some cool designs using a butterfly air impact wrench. I am exaggerating of course... have not even tried to reach the drawbar...

- Replace all metal emblems/badges... You can see the one for the model and serial number... all gone... - Was only able to get a new serial plate. The rest of the badges will remain as is.

- There is one knob for the Y axis lock that is not original... I think... need to check photos of other machines - New knobs and handwheel ordered, received, and installed

- Z-axis servo motor... Lazy? Yeah... If I can find a motor to drive the knee, without breaking the bank, that would be great.

- Replace bearing in pulley assembly

- Replace locking nut, R8 guide pin in quill

- Cover for rear of column

- Get R8 collect set

- Get keyless drill chuck - got a PM unit

Last edited:

- Joined

- Aug 6, 2015

- Messages

- 3,887

Ha! I did that before dividing the list in Pending and Done tasks... let me fix that!Makes me tired just reading your " done " list wachuco !

- Joined

- Nov 25, 2015

- Messages

- 8,314

as far as the quill goes. could it be the lock is on. On a BP the lock handle drops to lock... which has a habit of locking when you don't want it.

did you check it. Also when you were machining the plates for the pnuematic power bar, was it working well? if so, did a chip get lodged where it isn't supposed to be.

did you check it. Also when you were machining the plates for the pnuematic power bar, was it working well? if so, did a chip get lodged where it isn't supposed to be.

- Joined

- Aug 6, 2015

- Messages

- 3,887

as far as the quill goes. could it be the lock is on. On a BP the lock handle drops to lock... which has a habit of locking when you don't want it.

did you check it. Also when you were machining the plates for the pnuematic power bar, was it working well? if so, did a chip get lodged where it isn't supposed to be.

Quill Lock - I will check again, but does not feel like that is the problem. I will see if I can completely undo the lock to rule that out. I also need to check the mechanism that lowers it... to make sure it is not debris in the mechanism causing the problem...

Also thinking about removing the complete quill assembly and checking the shaft's splines for any burrs (I should have done this the first time I took it out... ) But it came out fine and went it without issues... so doubt it is that...

I machine the plates at the other house in Orlando... only did assembly in Ocala... so no chips anywhere when I was doing this.

I also checked what @paulymorph suggested in post #193 in this thread... but did not solve the issue.

Obviously, it is something I did or overlooked... And for the life of me, can't remember if it was like that when I bought it.... shame on me...

I will work on this next because it is bugging me to no end...

Last edited:

- Joined

- Aug 6, 2015

- Messages

- 3,887

- Joined

- Aug 6, 2015

- Messages

- 3,887

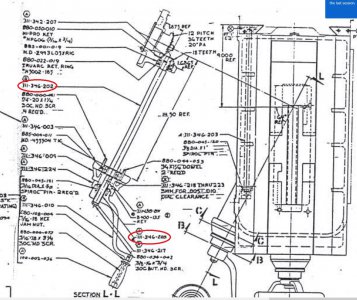

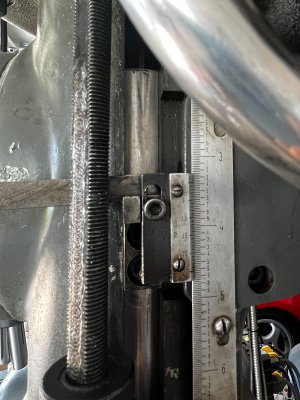

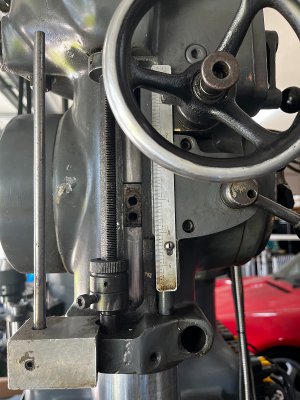

And here you can see what I mean by a bent shaft on the knee shaft

Part number confirmed. Part #111-346-202 is the elevating shaft and is $194.60 plus shipping.

I am thinking... it is a rod/shaft... right? Straight shaft with some key slots in it.... right? Nothing fancy? Hummmm

Part number confirmed. Part #111-346-202 is the elevating shaft and is $194.60 plus shipping.

I am thinking... it is a rod/shaft... right? Straight shaft with some key slots in it.... right? Nothing fancy? Hummmm