- Joined

- Oct 7, 2020

- Messages

- 2,115

The quill does seem pretty tight, and it sounds like your just about to the bottom of it.

Yes. It should be smooth... It is not....The quill does seem pretty tight, and it sounds like your just about to the bottom of it.

...

...

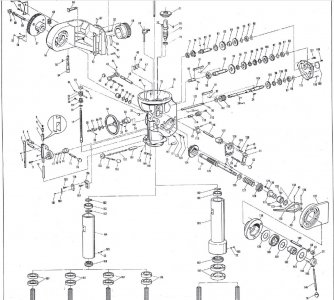

So funny you mentioned this. I didn't check but i'm not sure if the keys toward the front align with the keys on the back but maybe they do. I shoulda checked. grrr... However, in disassembling yesterday to take those pics, I pulled it out in about the 4 o'clock position and I dropped the key 5-6 times when trying to put it back in.@paulymorph, you rock!! I already order the part... My concern was having to disassemble the table and all that to get to where I could remove that shaft...

So the only concern would be to make sure the key is in the up position to avoid that falling when reinstalling... cool!!

Shaft arrives today to Orlando... I will be able to check if the keyways are aligned and plan ahead when removing/replacing.So funny you mentioned this. I didn't check but i'm not sure if the keys toward the front align with the keys on the back but maybe they do. I shoulda checked. grrr... However, in disassembling yesterday to take those pics, I pulled it out in about the 4 o'clock position and I dropped the key 5-6 times when trying to put it back in.. It just fell in a small dish right below the opening and I was able to retrieve it with one of those little 4 claw spring-loaded grabber tools. Should also be easy enough to shim the side of the key with a small piece of paper if it's too loose though.