- Joined

- Aug 6, 2015

- Messages

- 3,892

Same here.I first pick up the long stringy swarf by hand (gloved) or magnetic wand, then vacuum, finally wipe with a rag.

Same here.I first pick up the long stringy swarf by hand (gloved) or magnetic wand, then vacuum, finally wipe with a rag.

I use a similar style Dewalt wall mounted vacuum that's dedicated to the mill. However, the hose is only 1 7/8" diameter. Long stringy chips do occasionally plug up the hose. To clean out the hose I disconnect it from the vacuum. Drop the connector end into a 5-gallon bucket and drop about a foot long piece of 1" steel round stock down the other end. It takes a few minutes, but eventually all the swarf is cleaned out. It's a filter style only. No bag.I have had good performance from Craftsman vacuums. Get a large diameter hose, say 2.5”. I keep it central between the mill, lathe, vertical bandsaw and horizontal bandsaw, and it’s easy to dump the bin when needed. The long chips eventually will jam the hose, so choose feeds and speeds to break them up.

Don’t ever think that the dust collector from your wood shop will work. It’s for dust!

I don't know whats available in Spain but I have one of these next to my mill.

Bucket Head 5 Gallon 1.75 Peak HP Wet/Dry Shop Vacuum Powerhead with Filter Bag and Hose (compatible with 5 Gal. Homer Bucket) BH0100 - The Home Depot

The Bucket Head Wet/Dry Vac Powerhead can be used to turn a The Home Depot brand 5 gal. multi-use bucket (sold separately) into a powerful wet dry vacuum. The powerhead features a 1.75 peak horsepowerwww.homedepot.com

Works for me and cheap.

John

I use a similar style Dewalt wall mounted vacuum that's dedicated to the mill. However, the hose is only 1 7/8" diameter. Long stringy chips do occasionally plug up the hose. To clean out the hose I disconnect it from the vacuum. Drop the connector end into a 5-gallon bucket and drop about a foot long piece of 1" steel round stock down the other end. It takes a few minutes, but eventually all the swarf is cleaned out. It's a filter style only. No bag.

I have several other wet dry vacuums in the shop. All of these are roll around Shop Vac brand. All have the 2 1/2" hose and use filters without the bags. The hose on these machines have never plugged with swarf. To empty the contents, I just remove the top, slide a garbage bag over the top, then flip the canister upside down and empty the contents into the bag. Word of caution don't let the vacuum fill more than about 30%. Any more and it's hard to handle. Not only that the garbage bag won't be able to carry the weight.

I also have a dust collector for the wood working equipment. I wouldn't try it for metal swarf. The oily mess will coat the inside of the hose and the impeller in the blower. The oil will also ooze through the collection bags and make it harder or impossible for air to pass through. Saw dust will then coat the inside of everything.

+1 on the ShopVac switches not being very good. I have the ShopVac pictured below, which works okay when it's running, but the ON switch is finicky. I attached a 5-gallon bucket with one of those vac-attach lids to my ShopVac. Cut the hose short from the shop vac to the bucket, then a long one from the bucket. The heavy stuff goes into the 5-gallon bucket for dumping.

I also have a 5-gallon bucket with the vac-attach at my sandblaster. Amazing how much easier it is to see in the cabinet with some vacuum on it.

I don't know the CFM on the 5-gallon pail all-in-ones, but at $30 it'd be worth a hard look.

Bruce

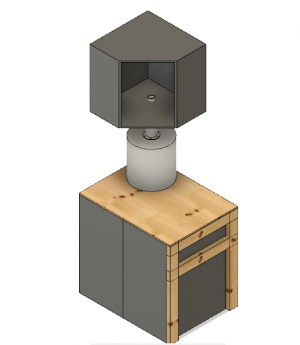

View attachment 426200

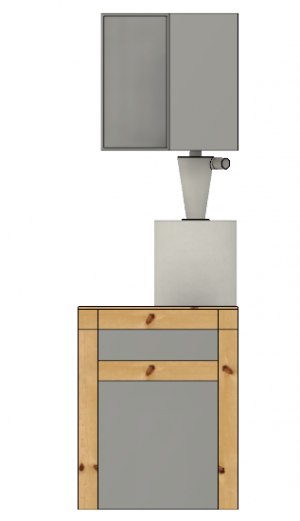

View attachment 426203

I have a small rigid in an overhead cabinet in the wood shop, connected to a dust deputy on a 5 gallon fiber barrel.

However, I second this solution for the metal shop because I hate oily swarf and it hates filters, but I recommend a two bucket solution to prolong the life of the vacuum significantly. The two bucket solution places a dustopper separator in series with and ahead of the bucket head. Most of the oil and chips will separate out prior to reaching the second bucket and the filter head of the vacuum.

BONUS noise abatement... you can place the second bucket in an insulated cabinet or cupboard with a remote switch and almost never need to access it. The first pail with the dust topper can be placed where you have easy access to drop the bucket for to empty it. This is how it is in my wood shop.

The dust topper is great in height constrained systems... but is not as effective as the dust deputy...That is pretty cool... another gadget I did not know about...

Dust Separator at Home Depot - 50.00 at the local HD

The one from Amazon does not include the additional hose that would be needed to connect it inline..

Dust Separator at Amazon

About a year ago I posted what I use in another thread, but can't find any of my posts that are that old. However, this is my current setup:Hello.

My shop is a mess. Always a lot of chips of metal everywhere, and I don´t mean the floor, that is easy to sweep. I mean the lathe, the mill, etc... (they are mini)

So I looking for a vaccum cleaner, but there is to types: With disposable bag or with a filter that you clean. What typer is better for metal chops and that kind of things?

Off course course I won´t use it for long chips, these are easy to remove by hand

Thank you

Best regards