Which handle is broken?

Maybe I'm missing something... the only handle I don't see is the backgear engagement... it looks like all the apron controls are there...?

-Bear

I agree with Bear... I can't see what handle is broken. The apron selection shifter is still there (at least in the photos).

SLK "color me confused" 001.

Confusing on my part—sorry. In the post from a couple of days ago, when the lathe was buried in junk, the carriage drive handle (the one on the left) isn’t in the apron but is resting in the chip tray over by the tail of the bed.

I just stuck it in place to see if it fit in brittle fracture and had left it there for the last picture after cleaning up the area.

I did drop the apron a bit and propped up the carriage to look in there, and nothing seems jammed. But of course I’ll take the apron apart and try to understand what happened. My guess is Uncle’s assistant at some point couldn’t get it to move, and leaned on it too hard, maybe with a pry bar.

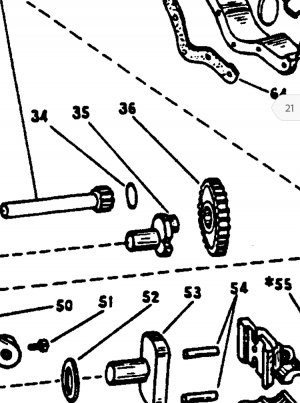

The part itself is #35 on the parts diagram below—the is the 1995 parts book that shows it as NLA for the 14-1/2.

@tq60 that’s exactly what I was thinking, but even easier than I was thinking. There is definitely enough topology in the fracture surface to interlock solidly. A half-inch bolt sounds about right. I don’t care if the head remains—I’m a fixer not a restorer.

Rick “a little upset earlier but feeling better now” Denney