That goes for many things! It's key to have a proper starting point. At least a sense of direction. I may scrap a few chucks getting it dialed in but I'll get itThere is quite a bit of “knowing how” when it comes to grinding - experience matters. One can read lots of How To books, watch a ton of videos, and listen to the advise of others. Those are good things to do, but there is no substitute to get out to the shop and grind some metal. Try out the different wheels, try to make every job better than the last: more square, size to +/-0.0001” of target, a better surface finish, different types of metal, . . . . Etc.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surface Grinder rookie

- Thread starter S5rx7

- Start date

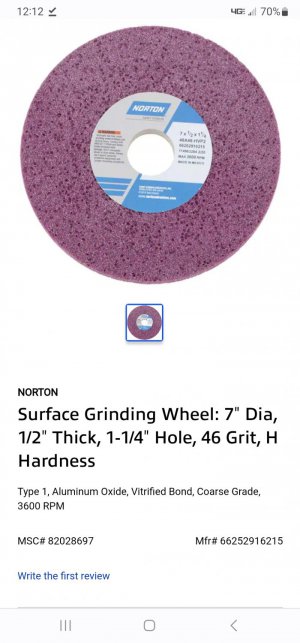

I'd opt for a ceramic( and preferably porous, if you're grinding dry ) wheel in 46H/I/J range, and start making sparks. One thing I've noticed so far is how the grind sounds. Right after a fresh wheel dress......that's how it should sound. If you're grinding away, and all of a sudden the sound of the pass changes; stop and re-dress the wheel. Same goes for the surface finish. If it changes, dress the wheel.That goes for many things! It's key to have a proper starting point. At least a sense of direction. I may scrap a few chucks getting it dialed in but I'll get it

Good info. I'm building a coolant rig. Gotta have it.I'd opt for a ceramic( and preferably porous, if you're grinding dry ) wheel in 46H/I/J range, and start making sparks. One thing I've noticed so far is how the grind sounds. Right after a fresh wheel dress......that's how it should sound. If you're grinding away, and all of a sudden the sound of the pass changes; stop and re-dress the wheel. Same goes for the surface finish. If it changes, dress the wheel.

- Joined

- Oct 15, 2020

- Messages

- 208

I'm gonna take a risk and give a suggestion. Resume: I ran the grinder room at the T&D shop where I apprenticed - scary drop in the deep end to be a noob AND the last guy to touch $100,000.00 assemblies. Ran a manual Micromaster, a Chevy (Chevalier) 2/3 auto and a big fully-auto (whose name escapes me, and it's super irritating me!). Too many hours staring at smelly yellow liquid, sparks, and rhythmic grrr..kachunk noises

Your cross-feed/step-over/sweep is more important than it may seem. Plunge depth is not as important (!!Blasphemy!!).

Yes, yes - take a tenth to get a decent finish, but you can actually sweep 0.025" - 0.050" off of a part without blowing the wheel or warping the part if you're judicious with your cross-feed. Those are extreme numbers that I've done - but 0.005" - 0.015" was a normal cut for me on small things - A2 and D2. Even did this on CPM coining dies that had a mile to go. Eats up the wheels, but also eats up the metal.

When you dress the wheel, you make a sharp corner - that is gone in the first spark. Work a bit, and the wheel develops a wedge shape, such that the back portion of the wheel is leaving the finish, but the front is hogging material (a thou is hogging on a grinder). The wedge makes all of this possible.

My point is that you want to take Shaper-like cuts, rather than rasp-like abrasions. Doing this puts most of the heat loading into the swarf, whereas plunging puts most of the heat into the part.

Spark the part for a 0; drop behind the part whatever depth you choose - 0.0002" for a light touch, 0.005" if you have a long way to go. With the wheel behind the part, begin rocking the table. Feed into the wheel in a face-like operation, giving the LIGHTEST touch on your cross until the wheel understands your intentions. From there, it's your courage and the machine's response that determines what you do. ALWAYS feed against the wheel's direction (but, "always" is a relative term )

)

Try to avoid any situation where the wheel feels like it is supposed to drive up onto the part. I preferred these super-porous red wheels for this type of operation. Cannot remember their name, but if you looked at them wrong, they would remove your skin for you. I want to say 60 grit, but I'm probably remembering that wrong. Will need to dress ALOT.

Specific to chuck grinding, it seems mist might work, but I'm more inclined to DROWN that thing - if you could do it under-water, all the better!

Long passes in a plungy-type situation WILL warp the part. It is counter intuitive, but it is far-far-far faster to use the surface grinder as a shaper-like-horizontal-face-mill-thingy, than it is to take 1/2 or whole wheel-width plunges, 0.0001" at a time.

Don't think of it as a grinder - think of it as an "Abrasive, self-sharpening, long-pass Shaper".

I do hope I've not angered anyone with my blasphemous, heretical technique - this method worked REALLY well for me, and I got to the point where I'd run all three grinders simultaneously and move those parts off of my bench. Ate a lot of wheels, but man I could grind fast!

And, I hope it goes without saying that 1. Last pass AFTER the part is COLD and 2. Your shop, your tool, your risk!

Your cross-feed/step-over/sweep is more important than it may seem. Plunge depth is not as important (!!Blasphemy!!).

Yes, yes - take a tenth to get a decent finish, but you can actually sweep 0.025" - 0.050" off of a part without blowing the wheel or warping the part if you're judicious with your cross-feed. Those are extreme numbers that I've done - but 0.005" - 0.015" was a normal cut for me on small things - A2 and D2. Even did this on CPM coining dies that had a mile to go. Eats up the wheels, but also eats up the metal.

When you dress the wheel, you make a sharp corner - that is gone in the first spark. Work a bit, and the wheel develops a wedge shape, such that the back portion of the wheel is leaving the finish, but the front is hogging material (a thou is hogging on a grinder). The wedge makes all of this possible.

My point is that you want to take Shaper-like cuts, rather than rasp-like abrasions. Doing this puts most of the heat loading into the swarf, whereas plunging puts most of the heat into the part.

Spark the part for a 0; drop behind the part whatever depth you choose - 0.0002" for a light touch, 0.005" if you have a long way to go. With the wheel behind the part, begin rocking the table. Feed into the wheel in a face-like operation, giving the LIGHTEST touch on your cross until the wheel understands your intentions. From there, it's your courage and the machine's response that determines what you do. ALWAYS feed against the wheel's direction (but, "always" is a relative term

Try to avoid any situation where the wheel feels like it is supposed to drive up onto the part. I preferred these super-porous red wheels for this type of operation. Cannot remember their name, but if you looked at them wrong, they would remove your skin for you. I want to say 60 grit, but I'm probably remembering that wrong. Will need to dress ALOT.

Specific to chuck grinding, it seems mist might work, but I'm more inclined to DROWN that thing - if you could do it under-water, all the better!

Long passes in a plungy-type situation WILL warp the part. It is counter intuitive, but it is far-far-far faster to use the surface grinder as a shaper-like-horizontal-face-mill-thingy, than it is to take 1/2 or whole wheel-width plunges, 0.0001" at a time.

Don't think of it as a grinder - think of it as an "Abrasive, self-sharpening, long-pass Shaper".

I do hope I've not angered anyone with my blasphemous, heretical technique - this method worked REALLY well for me, and I got to the point where I'd run all three grinders simultaneously and move those parts off of my bench. Ate a lot of wheels, but man I could grind fast!

And, I hope it goes without saying that 1. Last pass AFTER the part is COLD and 2. Your shop, your tool, your risk!

Great info @MERLIncMan , thanks for sharing your experience! Is what Adam describes in this video as "peel grinding" the basic gist of what you're describing?

- Joined

- Oct 15, 2020

- Messages

- 208

Great info @MERLIncMan , thanks for sharing your experience! Is what Adam describes in this video as "peel grinding" the basic gist of what you're describing?

Neat! I don't know what it's called, I just know the smell of the dust that it makes....

Yes, it seems that this is what I was doing.

- Joined

- Feb 5, 2018

- Messages

- 638

There is a video about this technique on u tube. Don Bailey from Suburban Tool did it. He has about 100 years experience grinding and has some great information about it.

Joe

Joe

- Joined

- Nov 10, 2022

- Messages

- 5

There has been a lot of great information shared already so forgive me if this is repetitive. I tried to keep this brief but it is tough.

A couple of notes on successful grinding starting from the beginning.

A couple of notes on successful grinding starting from the beginning.

- The machine must be leveled to a very high sensitivity.

- A .0005"/foot or better level is required.

- The machine table should be inspected for flatness before mounting the chuck

- The table can be ground if it is not within .0002" flatness over the chuck mounting area.

- The chuck must be inspected for flatness/parallelism before mounting.

- If the bottom is not flat, it should be blocked in, top side down and ground flat.

- Blocking it in and shimming any twist/warp will keep from reproducing the same defect.

- Do not use the magnet or clamp to hold it it down.

- If the bottom is not flat, it should be blocked in, top side down and ground flat.

- Mount the chuck..

- Assemble the rail in order to indicate in straight in the x axis direction

- clamp the chuck, 15 foot pounds on the left and 10 foot pounds on the right.

- This is to allow for heat expansion.

- Magnet on or magnet off?

- Permanent magnets, always on.

- They do not create heat when on.

- Electromagnetic chucks turned on with power reduced to below 30% or off

- They will create heat and the reduced power helps

- Never leave them on at full power for long periods unless you have flood coolant running.

- Electro permanent chucks

- Perform just like Permanent magnetic chucks

- Permanent magnets, always on.

- Grinding the chuck (top, bottom or table)

- A course dress is recommended

- Down feed should not exceed .0002"-.0003" (Y-axis)

- Cross feed should be about .050" to .100" per stroke (Z-axis)

- Traverse speed (X-axis) should be fairly rapid

- You will want to do several spark outs

- If you have coolant, use it!

- smearing wax on the chuck between cuts works

- Smearing cutting oil on the chuck between cuts works as well or better.

- Mist coolant works better and flood coolant is best.

- With care, a chuck can be ground dry. Leave electromagnetic chucks off and wait for the surface to cool to ambient between cuts.

. Picking one and going with it.

. Picking one and going with it.