Yes! I down loaded the Norton wheel brochures . I'm more confused now than I ever was . I'm going to research the wheel you suggested. Thanks.There's a lot of alphabet soup when it comes to grinding wheels. Right up there with carbide inserts! I still don't have it figured out, and simply went with the advice of a friend who owned his own grind shop for a number of years. For general purpose grinding a Norton 5SG 46H VSP. The 5SG designates it as a ceramic alox. 46H is 46 grit H hardness, and the VSP is for a porous matrix, which gives it a lot more room for the scarf to go without plugging up the wheel. The porous matrix, along with the ceramic, made a huge difference for me over the plain white alox wheels that came with my grinder. I had to dress them constantly, as they would start plugging up after just a few passes; either dry or with mist. When I switched to the ceramic wheel the difference was amazing. I ground the top surface of a 3" x 4" block of 4140 with it, and when finished, you couldn't even tell that I had used it. Looked freshly dressed. Planning to get another in 60 grit, for times I'd like a finer finish.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Surface Grinder rookie

- Thread starter S5rx7

- Start date

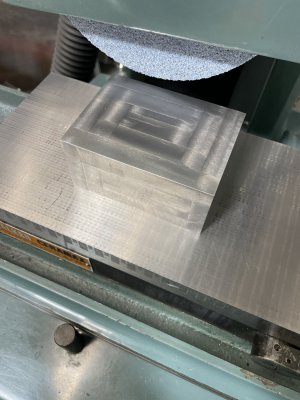

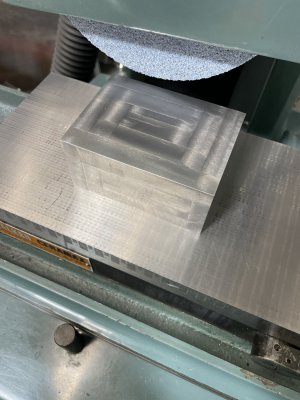

Got curious about as to whether a mist cooler actually cools the part, or simply cools the tool. After using one for a bit, I suspected it was the former, but wanted to confirm what I'd observed. So I mag'd down a 2" x 3" x 4" block of normalized 4140 to measure the before/after temps and removed a total of .002" using 8 passes of .00025" per pass. Granted these are pretty light cuts, but that's how I'll be using this grinder. I'm fortunate to have a mill that will hold parts to .0005" or better, so I mill as close to size as I can, to reduce the need to grind.

Here's what I started with.

It was at ambient temp of 64.7F

After taking 8 passes, and removing .002", I stopped the mist right away, and checked the temp of the part. It was 59.9F; nearly 5F cooler than it was before the start of the grind. I'd say it's a safe bet to say that it does indeed help cool the part.

After checking the temp, I resumed grinding to do the spark out passes, as I wanted to do the temp check immediately following the heavier cuts. After the spark out, this is the result, along with an indication of the "mess" left behind afterwards.( the mister used about 2-3 oz of coolant ) I didn't attempt to clean up anything, other than wiping off the ground surface.

Here's what I started with.

It was at ambient temp of 64.7F

After taking 8 passes, and removing .002", I stopped the mist right away, and checked the temp of the part. It was 59.9F; nearly 5F cooler than it was before the start of the grind. I'd say it's a safe bet to say that it does indeed help cool the part.

After checking the temp, I resumed grinding to do the spark out passes, as I wanted to do the temp check immediately following the heavier cuts. After the spark out, this is the result, along with an indication of the "mess" left behind afterwards.( the mister used about 2-3 oz of coolant ) I didn't attempt to clean up anything, other than wiping off the ground surface.

Love some basic R&D! The part definitely would stay cooler as long as the coolants same as ambient or below. My mind is on overload. Between figuring out grinding wheels and different carbid inserts for tooling. I've been at this all day with maybe 1hr break.

Yes.akjeff, I assume the wheel was dressed before grinding?

Just curious..

- Joined

- Feb 5, 2018

- Messages

- 638

- Joined

- Feb 5, 2018

- Messages

- 638

- Joined

- Feb 5, 2018

- Messages

- 638

Get a 46g. H or I hardness and do some grinding. It will take a little practice to get good results.

Joe

Joe

- Joined

- Sep 25, 2014

- Messages

- 1,111

There is quite a bit of “knowing how” when it comes to grinding - experience matters. One can read lots of How To books, watch a ton of videos, and listen to the advise of others. Those are good things to do, but there is no substitute to get out to the shop and grind some metal. Try out the different wheels, try to make every job better than the last: more square, size to +/-0.0001” of target, a better surface finish, different types of metal, . . . . Etc.