- Joined

- Sep 8, 2019

- Messages

- 4,392

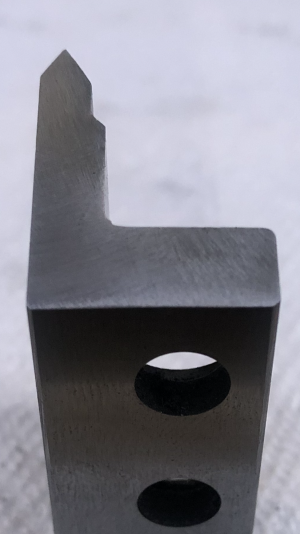

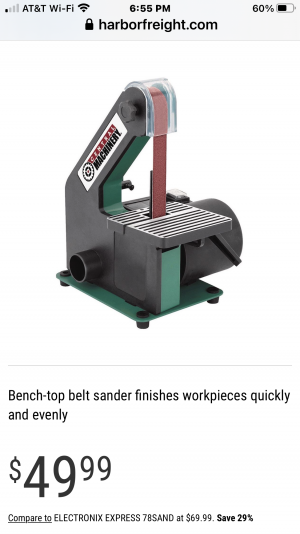

To sharpen a P6, you grind the entire top flat. You have a lot to grind away but if you just make the top flat it will reproduce the original geometry. Best done on a belt sander.

Perfect timing with your answer. But what if I don’t have a belt sander?

I can’t use a milling machine with a carbide end mill? I did that before, but I ground it at an improper angle.

Last edited: