- Joined

- Sep 8, 2019

- Messages

- 4,392

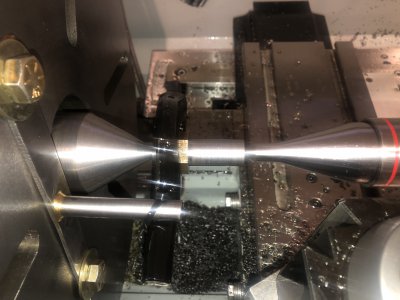

You gotta rub some dirt on that driving dog or something! That makes the paint in my newish truck look dull in comparison.

Do you wax that thing? It's downright pretty.

In a local native dialect Skookum means strong or powerful, like the Skooumchuck river in WA. Or for jail you say Skookum houseI absolutely welcome constructive criticism. What is skookumness?

Edit: I looked it up, and I got that skookum means cool or impressive.

Looks good! Sorry, I should use proper words. I tend to use it as a catch all for sturdy, rigid, beefy. I blame a certain YouTuber!

I reckon a bit of triangulation from the end of the driver rod to near the bolts would work wonders for stiffening the driver up and hopefully help your surface finish. Won't need much, just enough to stop any potential for flexing/ringing of the plate/rod.