Hello Cal,

Pulled the rear bearing cleaned and repacked and reassembled. The grease was about the consistency of modeling clay. I pulled the front cover off and can't tell how to unload that bearing. Or does the cover hold it in place while the rear spanner nut loads both bearings? If that's the case removing the set screw shown at the top should let me get that"collar" off and reveal the bearing. Am I on the right track?

...

Hi Les,

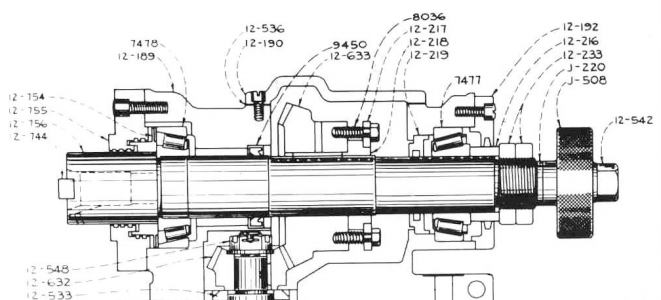

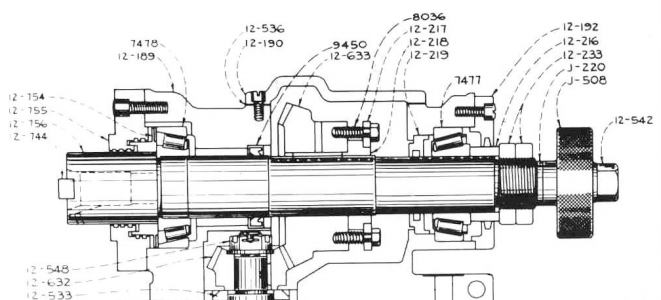

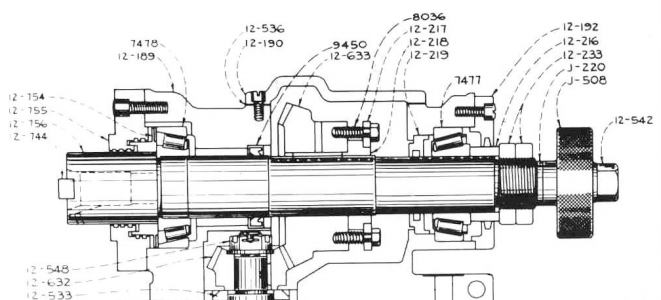

Here's a drawing of your cutter-head:

The "collar" is 12-754. It and the end cap form a labyrinth seal that was used in lieu of an oil seal. It allows excess grease to escape through the labyrinth. These heads had a reputation for spitting like an angry camel, due mostly to over greasing.

If you don't have the manual with that drawing in it, send me an e-mail and I'll send you a copy.

You should be able to loosen the setscrew and remove 12-754. This will give you access to the bearing. You can flush out the old grease and repack without taking the spindle apart. The only way to get the bearing out of there for thorough cleaning is to disassemble the spindle, which I DO NOT recommend.

Since you had to remove the threaded collars on the back (J-220) to get to the rear bearing, you will have to adjust the pre-load on the bearings: Set the head horizontal. Protect the end of the spindle with block of wood and use a dead blow hammer to tap the spindle to the rear, loading the front bearing. Set an indicator against the face of the spindle and set it to zero. Lift the indicator off of the spindle and tap on the back of the spindle to load the rear bearing. Note the difference in indicator readings. Repeat your readings a few times to make sure that you're getting the same reading each time. You should see between 0.0005 and 0.0008" difference in readings. Adjust the backlash by tightening or loosening the inner threaded collar, then hold it with a spanner and tighten the outer collar to lock it in place. Recheck the backlash after you finish tightening the collars.

Did you take any photos of the rear bearing?

What's the serial number of your machine? (You can find it stamped on the top of the vertical dovetail way for the knee.)

Cal