ok, Im back at this!!

I managed to get the table off with Cals suggestions of removing the gib and the entire table slid right off no problem( took it off by sliding it to the left)

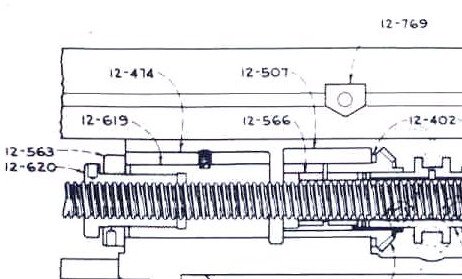

But the lead screw is still jammed.. so I ordered a few spanners from McMaster and I am posting these in the hope that the VanNorman Gods will take pity on me...

It looks as if the brass spanner nut is deformed.. maybe from the crash.. -probably from the crash...

as I was saying before, the lead screw is completely static.. stuck .. so I am really at a loss here..

I managed to get the table off with Cals suggestions of removing the gib and the entire table slid right off no problem( took it off by sliding it to the left)

But the lead screw is still jammed.. so I ordered a few spanners from McMaster and I am posting these in the hope that the VanNorman Gods will take pity on me...

It looks as if the brass spanner nut is deformed.. maybe from the crash.. -probably from the crash...

as I was saying before, the lead screw is completely static.. stuck .. so I am really at a loss here..