-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pm935 Owners

- Thread starter wrmiller

- Start date

- Joined

- Jun 12, 2014

- Messages

- 4,810

You may consider bringing in 4 wire to your machine, the VFD only needs 2 hots and a ground. I have accessory electrical boxes/outlets on my mill to run 230V equipment (axis drives, coolant pump) and 120V (DRO, lights). I only have a single extension cord running to the mill. If you are adding an electrical box, use a master power switch, you can put a DIN rail and drop in supplemental breakers or fuses for the different breakout circuits. Automation Direct supplemental DIN rail breakers are ~$20 a unit.

- Joined

- Oct 23, 2015

- Messages

- 217

Nice ill look into it. Im waiting currently for a more permanent electrical solution before I take that plunge.

Sent from my LG-LS980 using Tapatalk

Sent from my LG-LS980 using Tapatalk

- Joined

- Mar 21, 2013

- Messages

- 4,063

Would auto-tune the VFD to the motor. I can but together a parameter file if needed.

Jim's suggestion of putting the VFD in the machine, may not be unreasonable, can't see doing any program changes once it is up and running. There is always the USB port.

Dude, I completely missed this. If you have the time and don't mind, I'd love a parameter file. The one you did for my 1340GT was perfect.

What's "auto-tune"? Pretty sure I didn't do that with the lathe. Should I go back and do this?

And I like the idea of the USB port. May have to put a connector on the access panel. Thanks!

- Joined

- Mar 21, 2013

- Messages

- 4,063

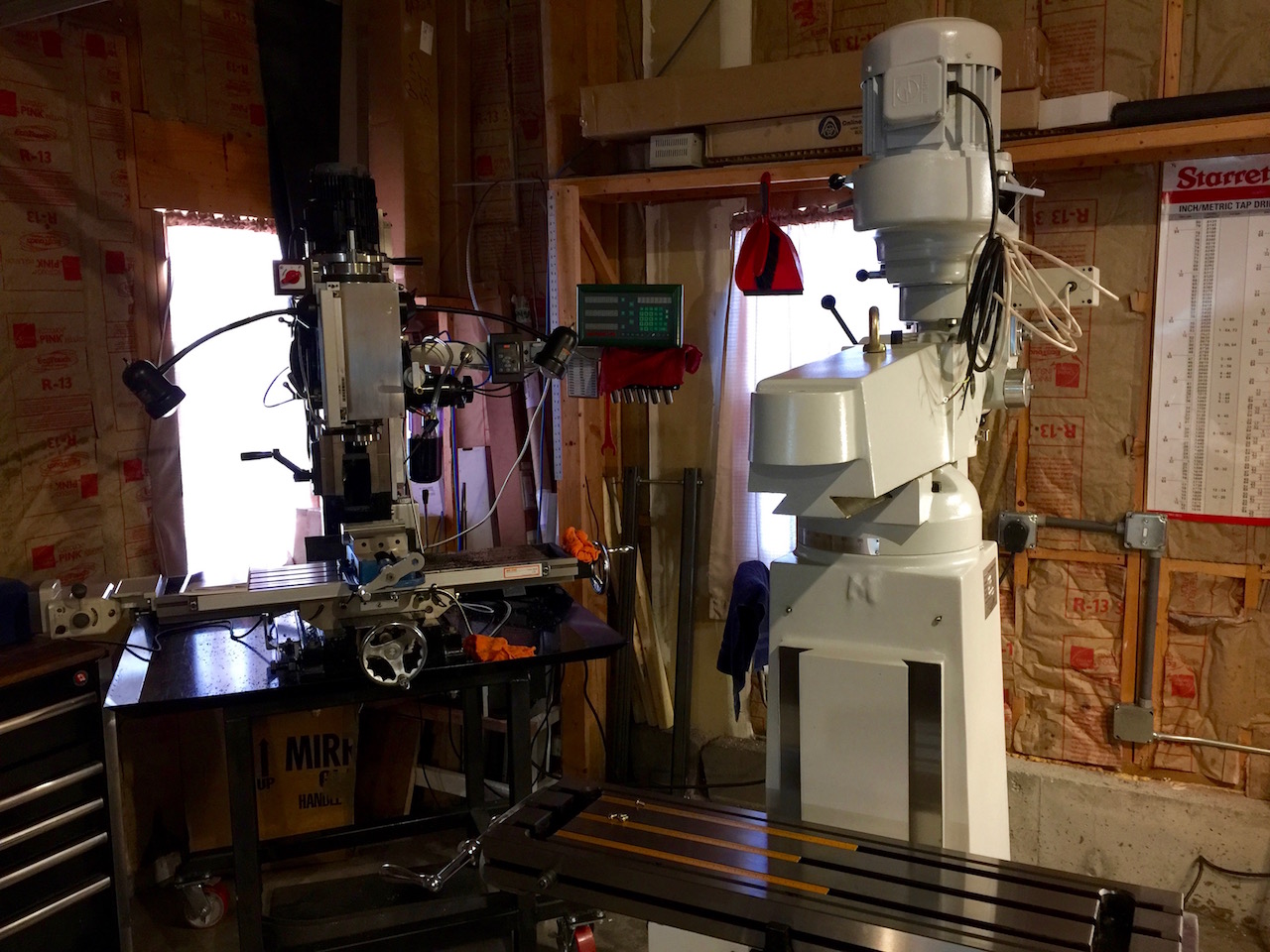

Just about ready for the stand. I need to cut the sides off the pallet (seems a crime, this pallet is very well built) to get the 2T hoist in position. We're going to pick this thing up just enough to clear the pallet, then slide the stand under the mill. Once bolted to the stand I'll not lift this thing again.

Size/footprint wise, the 935 is near identical to my 12z. The 12z has a larger table, but the one on the 935 is thicker. And you should see the size of the screws on the 935. The 935 on it's pallet sits 8.5" off the concrete. Chris is telling me that the stand he is building will have the mill at the same height. At that height, the hi/low range lever on the front right is just below eye level. This means I'll be stooping a bit, but hopefully it won't be too bad.

Just for giggles...

For the more observant: I have the head rotated 180 degrees to better balance the weight. This puts the eyelet near centered on the column and I hope to be able to move the table forward or back to balance the lift. And I did ask Matt if I could lift by the eyelet. He says they do it all the time.

Size/footprint wise, the 935 is near identical to my 12z. The 12z has a larger table, but the one on the 935 is thicker. And you should see the size of the screws on the 935. The 935 on it's pallet sits 8.5" off the concrete. Chris is telling me that the stand he is building will have the mill at the same height. At that height, the hi/low range lever on the front right is just below eye level. This means I'll be stooping a bit, but hopefully it won't be too bad.

Just for giggles...

For the more observant: I have the head rotated 180 degrees to better balance the weight. This puts the eyelet near centered on the column and I hope to be able to move the table forward or back to balance the lift. And I did ask Matt if I could lift by the eyelet. He says they do it all the time.

Last edited:

- Joined

- Oct 23, 2015

- Messages

- 217

Im workin on it!Just about ready for the stand. I need to cut the sides off the pallet (seems a crime, this pallet is very well built) to get the 2T hoist in position. We're going to pick this thing up just enough to clear the pallet, then slide the stand under the mill. Once bolted to the mill I'll not lift this thing again.

Size/footprint wise, the 935 is near identical to my 12z. The 12z has a larger table, but the one on the 935 is thicker. And you should see the size of the screws on the 935. The 935 on it's pallet sits 8.5" off the concrete. Chris is telling me that the stand he is building will have the mill at the same height. At that height, the hi/low range lever on the front right is just below eye level. This means I'll be stooping a bit, but hopefully it won't be too bad.

Just for giggles...

View attachment 121564

For the more observant: I have the head rotated 180 degrees to better balance the weight. This puts the eyelet near centered on the column and I hope to be able to move the table forward or back to balance the lift. And I did ask Matt if I could lift by the eyelet. He says they do it all the time.

Sent from my LG-LS980 using Tapatalk

- Joined

- Jul 23, 2014

- Messages

- 347

Will your shop crane reach high enough?

- Joined

- Mar 21, 2013

- Messages

- 4,063

I don't see why not. The 935's attachment point is lower, and I only need to lift it a couple of inches or so. The attachment point/strap's rings on the 12z had me having to extend the hoist a lot higher to overcome the tilt of the 12z when I lifted it. I'll have a harder time getting the 12z off it's stand.