-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oxy/acetylene rig

- Thread starter DavidR8

- Start date

- Joined

- Oct 16, 2019

- Messages

- 6,581

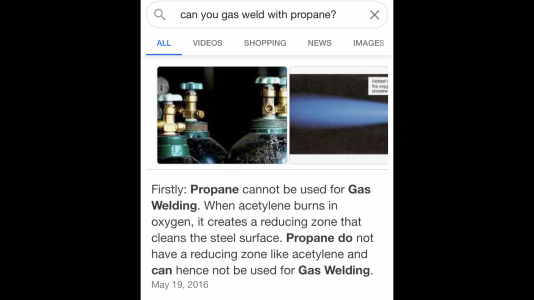

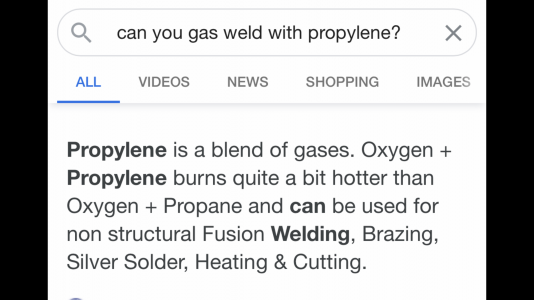

I'll definitely take you up on the tank!If you aren’t planning to weld then I would seriously consider oxy / propane. Way less hassle and cost than acetylene. Propane is available everywhere every day.

Don’t forget that oxygen bottle that is available closeby

I'll definitely take you up on the tank!

No pressure. ( oops no pun intended ) I’m here to help you figure out the best plan to suit your needs.

For what it is worth - I didn't research a whole lot before I got my O/A torch kit. I was doing a lot of work on my 1 ton truck and gearing up for it I wasn't going to start in to the project without a torch by my side. What I ended up doing was I bought the Harbor Freight kit with the bottles for around $350.

If I had researched things further I would have bought a torch kit then the next size up bottles from the LWS.

The place I deal with here was a bit picky on the bottles from the HF kit. What they do is run an exchange service. So you bring empty tanks to them then they exchange a filled and certified set. So they wanted me to swap my brand new tanks. That ****** me off, but we worked it out and they agreed to put them in their cycle to check them out and if they checked out they filled them - which they did. It took about 8 or 9 days to get the tanks back.

If I get in to more gas cutting or welding then I will need bigger tanks. At that point I can go to the LWS and get a set of exchange tanks of what ever size. Then I can keep the small set as a back-up. Maybe run the small set empty, then refill and not use.

One other point to make (I didn't read every reply in the thread so someone may have already covered this) is that Acetylene is dissolved in a material in the tank. The acetylene tanks are NOT hollow tanks. When you use acetylene it has to bubble up from the material it is dissolved in. Think of carbonated drinks, like tonic. The carbonation bubbles come up to the surface when you unscrew the cap and let the pressure out. This is very similar.

The reason the dissolved acetylene concept is important is that you can only draw the volume of acetylene that has accumulated at the top of the bottle. If the rate of refilling that is slower than what you are consuming with your torch you are going to run out. So you can think of this as being the "duty cycle" of the acetylene bottle. Once you max out what you can draw you need to let the bottle sit so more acetylene can come out to the top.

You can draw a lot more acetylene quicker the larger the bottle you have. This is the #1 reason a bigger bottle set is a good thing to have.

Your gas supplier can fill you in on more specifics and actual numbers. If you know what you are going to be doing with your torch kit (heating up auto/farm equip parts for service work, cutting duty, metal bending duty, welding duty, etc, etc - and what size tips you will want to run for each application) you can have a better baseline from which to base tank sizes off of. Other than that, figure up what you think you need and get the next tank size bigger.

In any case, the best thing to do with tanks is to do the exchange deal. Its convenient and a heck of a lot less hassle from the get-go.

There is also a thread on Welding Web that has links to a google doc where people are posting their gas prices. It is an interesting document to look through. The thread started out of some discussions about how much people were paying for gases in different parts of the country and the world. Some people were getting quite ripped off whereas other seemingly were getting gas for the taking. Might be worth a look to see if anyone has posted anything in your region.

If I had researched things further I would have bought a torch kit then the next size up bottles from the LWS.

The place I deal with here was a bit picky on the bottles from the HF kit. What they do is run an exchange service. So you bring empty tanks to them then they exchange a filled and certified set. So they wanted me to swap my brand new tanks. That ****** me off, but we worked it out and they agreed to put them in their cycle to check them out and if they checked out they filled them - which they did. It took about 8 or 9 days to get the tanks back.

If I get in to more gas cutting or welding then I will need bigger tanks. At that point I can go to the LWS and get a set of exchange tanks of what ever size. Then I can keep the small set as a back-up. Maybe run the small set empty, then refill and not use.

One other point to make (I didn't read every reply in the thread so someone may have already covered this) is that Acetylene is dissolved in a material in the tank. The acetylene tanks are NOT hollow tanks. When you use acetylene it has to bubble up from the material it is dissolved in. Think of carbonated drinks, like tonic. The carbonation bubbles come up to the surface when you unscrew the cap and let the pressure out. This is very similar.

The reason the dissolved acetylene concept is important is that you can only draw the volume of acetylene that has accumulated at the top of the bottle. If the rate of refilling that is slower than what you are consuming with your torch you are going to run out. So you can think of this as being the "duty cycle" of the acetylene bottle. Once you max out what you can draw you need to let the bottle sit so more acetylene can come out to the top.

You can draw a lot more acetylene quicker the larger the bottle you have. This is the #1 reason a bigger bottle set is a good thing to have.

Your gas supplier can fill you in on more specifics and actual numbers. If you know what you are going to be doing with your torch kit (heating up auto/farm equip parts for service work, cutting duty, metal bending duty, welding duty, etc, etc - and what size tips you will want to run for each application) you can have a better baseline from which to base tank sizes off of. Other than that, figure up what you think you need and get the next tank size bigger.

In any case, the best thing to do with tanks is to do the exchange deal. Its convenient and a heck of a lot less hassle from the get-go.

There is also a thread on Welding Web that has links to a google doc where people are posting their gas prices. It is an interesting document to look through. The thread started out of some discussions about how much people were paying for gases in different parts of the country and the world. Some people were getting quite ripped off whereas other seemingly were getting gas for the taking. Might be worth a look to see if anyone has posted anything in your region.

The DEFINITIVE Welding Gas Costs Thread.

Click here to enter your welding gas cost information: ► Survey ◄ Then click here to view everyone else's responses: ► Responses ◄

weldingweb.com

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Sep 8, 2019

- Messages

- 4,392

With oxyacetylene (as opposed to oxypropane or oxypropylene), the heat comes faster. This makes for great puddling when gas welding.

I have never worked with oxypropane or oxypropylene, but I have done a lot of O/A and it has always done what I needed it to do.

I have never worked with oxypropane or oxypropylene, but I have done a lot of O/A and it has always done what I needed it to do.

Last edited:

- Joined

- Dec 23, 2019

- Messages

- 1,138

What do you want to do with the rig?

I don't own a setup, but use frequently at the steam railway. In 20 years, I've never seen or had cause to gas weld. If there's a MIG or stick set around, it's an entirely redundant process. If brazing, a TIG set also makes it obsolete. The O/A rig gets used purely for heating and cutting, with a propane setup being quite good enough and cheaper. Worth thinking about what you really need it for against what else you have available or plan to buy into. Plasma has pretty much taken over cutting plate too.

A mate of mine has a tiny little Micky Mouse size oxy/Mapp setup that he uses for occasion automotive stuff (mostly heating stuck bolts), which is surprisingly capable and super cheap also.

I don't own a setup, but use frequently at the steam railway. In 20 years, I've never seen or had cause to gas weld. If there's a MIG or stick set around, it's an entirely redundant process. If brazing, a TIG set also makes it obsolete. The O/A rig gets used purely for heating and cutting, with a propane setup being quite good enough and cheaper. Worth thinking about what you really need it for against what else you have available or plan to buy into. Plasma has pretty much taken over cutting plate too.

A mate of mine has a tiny little Micky Mouse size oxy/Mapp setup that he uses for occasion automotive stuff (mostly heating stuck bolts), which is surprisingly capable and super cheap also.

- Joined

- Feb 5, 2018

- Messages

- 638

Years ago I worked in an auto salvage yard and we cut literally hundreds of tons of large thick steel with propane.

I would never even think about gas welding when you have electric welders available.

Not sure about the cost of acetylene but I heard it got very expensive. I can have a 20lb propane tank filled for less than $10 right now. You can do a lot of work with that.

Joe

I would never even think about gas welding when you have electric welders available.

Not sure about the cost of acetylene but I heard it got very expensive. I can have a 20lb propane tank filled for less than $10 right now. You can do a lot of work with that.

Joe

- Joined

- Mar 26, 2018

- Messages

- 8,409

You can take that to the bank!The only time you run out of gas is Saturday afternoon after the LWS closes and it is an urgent job.

- Joined

- Oct 31, 2014

- Messages

- 444

My LWS charges an arm and a leg for Victor equipment; I can find them online for less than half of what the LWS charges.

Be very wary of these online claims. Often what they mean is 'Victor style' i.e. knockoffs from Trashcanistan. Genuine Victor (or any other good gear) is worth the price. If price is an issue (when isn't it?) keep watching craigslist and garage sales as welding stuff shows up pretty regularly as long as you don't have an urgent need.

Good luck

Stu