- Joined

- Nov 24, 2014

- Messages

- 3,178

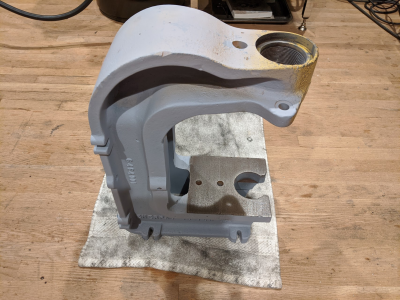

That is a good idea. I will look into it for the next mess!If you have a local auto engine rebuilding shop give them a call and ask about hot tanking it. It's usually pretty cheap and if you want it checked for cracks they can do that too.