-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: New Project

Bill, I have watched you do some incredible machining and I absolutetly love your work. I have cut alot of bearing tapers over the years,checking them with sine bars, and bluing them. Most all were cut using a Taper attachment. I have cut alot using the compound also. I have never tried using a form tool to do this. I would think it would be very hard to get an accurate taper. Also I would think chatter would be horrible. Im more of a blacksmith than a craftsman such as yourself. Please dont think I'm critisizing, I'm just tring to get a handle on this. Love your projects, please keep them coming.

Bill, I have watched you do some incredible machining and I absolutetly love your work. I have cut alot of bearing tapers over the years,checking them with sine bars, and bluing them. Most all were cut using a Taper attachment. I have cut alot using the compound also. I have never tried using a form tool to do this. I would think it would be very hard to get an accurate taper. Also I would think chatter would be horrible. Im more of a blacksmith than a craftsman such as yourself. Please dont think I'm critisizing, I'm just tring to get a handle on this. Love your projects, please keep them coming.

B

Bill Gruby

Forum Guest

Register Today

Re: New Project

Hello --- Once in a while you get a light chatter but it is acceptable and can be emoried out when done turning. The trick is speed and feed as always. You are only cutting .125 or less of the taper length at a time. start at the big end and work toward the small end. It takes some getting used to. I have been doing it this way for years. You also need good ears. The slightest chirp and you are at the end of the depth cut. Back it up, move it over start again.

"Billy G"

Bill, I have watched you do some incredible machining and I absolutetly love your work. I have cut alot of bearing tapers over the years,checking them with sine bars, and bluing them. Most all were cut using a Taper attachment. I have cut alot using the compound also. I have never tried using a form tool to do this. I would think it would be very hard to get an accurate taper. Also I would think chatter would be horrible. Im more of a blacksmith than a craftsman such as yourself. Please dont think I'm critisizing, I'm just tring to get a handle on this. Love your projects, please keep them coming.

Hello --- Once in a while you get a light chatter but it is acceptable and can be emoried out when done turning. The trick is speed and feed as always. You are only cutting .125 or less of the taper length at a time. start at the big end and work toward the small end. It takes some getting used to. I have been doing it this way for years. You also need good ears. The slightest chirp and you are at the end of the depth cut. Back it up, move it over start again.

"Billy G"

B

Bill Gruby

Forum Guest

Register Today

B

Bill Gruby

Forum Guest

Register Today

B

Bill Gruby

Forum Guest

Register Today

Re: New Project

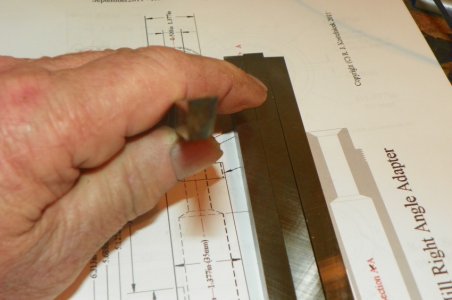

That's another project. It's a horizontal adapt. for my Clausing. It's an R8 nose taper I think.

"Billy G"

That's another project. It's a horizontal adapt. for my Clausing. It's an R8 nose taper I think.

"Billy G"

B

Bill Gruby

Forum Guest

Register Today

- Joined

- Nov 24, 2014

- Messages

- 3,164

Re: New Project

Bill,

The casting resin didn't work for you here but I'm curious what brand/type you used. I'm not experienced with casting resin and would be interested in your comments on the properties and past applications of what you used. I hope my interest isn't too much OT.

Congratulations on your project and progress. I'm waiting for a picture showing a pole w/line in the water.

Thanks,

Bill,

The casting resin didn't work for you here but I'm curious what brand/type you used. I'm not experienced with casting resin and would be interested in your comments on the properties and past applications of what you used. I hope my interest isn't too much OT.

Congratulations on your project and progress. I'm waiting for a picture showing a pole w/line in the water.

Thanks,

B

Bill Gruby

Forum Guest

Register Today

Re: New Project

I used a product called Easy Cast. Most craft stores will have it. It's biggest problem is the viscosity when mixed. It is thin to pour. Being thin will allow it to go anywhere it can. I did not take this attribute into account when I tried it. I chose this type because when completely cured it still possesses some resiliency. I will try it again one day.

"Billy G"

Bill,

The casting resin didn't work for you here but I'm curious what brand/type you used. I'm not experienced with casting resin and would be interested in your comments on the properties and past applications of what you used. I hope my interest isn't too much OT.

Congratulations on your project and progress. I'm waiting for a picture showing a pole w/line in the water.

Thanks,

I used a product called Easy Cast. Most craft stores will have it. It's biggest problem is the viscosity when mixed. It is thin to pour. Being thin will allow it to go anywhere it can. I did not take this attribute into account when I tried it. I chose this type because when completely cured it still possesses some resiliency. I will try it again one day.

"Billy G"