Parts look really good. Glad your getting the machine sorted out. I had some trouble with the change gears on my PM1127. On one of the gears, the keyed bushing had to be pressed out about .010" to keep the clip from rubbing on the face of the gear. I might make new pins and use a c-clip and shims in the future.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Pm 1030v Lathe

- Thread starter shooter123456

- Start date

- Joined

- Dec 1, 2014

- Messages

- 56

Wow, that looks amazing. I have just recently gotten time to play with my 1030v. I think I'm having the same problems you were having with changing gears. I did learn to figure out the order to stick the gears together for different threads but find the couplers are extremely tight and every time I changed gears had to use a punch to get it out. I will likely copy what you did and try some fine grit sandpaper to file them down a tiny bit and clean up the gears as well (I actually broke one coupler it was so tight trying to get it to go).

But glad you figured it out and it looks like you are off and running now. I'd love to see pics of your suppressor build and see how it turns out. Being in Canada those things are big time illegal so I can only dream of having one up here (but that doesn't stop me from watching you guys at work and seeing how they turn out). One day I may travel with my wife and check them out in a country that allows them but until that day I have to settle on hearing your guys stories.

But glad you figured it out and it looks like you are off and running now. I'd love to see pics of your suppressor build and see how it turns out. Being in Canada those things are big time illegal so I can only dream of having one up here (but that doesn't stop me from watching you guys at work and seeing how they turn out). One day I may travel with my wife and check them out in a country that allows them but until that day I have to settle on hearing your guys stories.

- Joined

- Jan 20, 2016

- Messages

- 602

I am finding more and more that the couplers are so fragile that anything more than light gentle pressure into the gears will cause them to deform. I will probably just buy a few extra gears for the threads I use most (actually I don't think I have ever done anything but 24tpi) or rig up a stepper motor to use instead so I don't need to change gears.Wow, that looks amazing. I have just recently gotten time to play with my 1030v. I think I'm having the same problems you were having with changing gears. I did learn to figure out the order to stick the gears together for different threads but find the couplers are extremely tight and every time I changed gears had to use a punch to get it out. I will likely copy what you did and try some fine grit sandpaper to file them down a tiny bit and clean up the gears as well (I actually broke one coupler it was so tight trying to get it to go).

But glad you figured it out and it looks like you are off and running now. I'd love to see pics of your suppressor build and see how it turns out. Being in Canada those things are big time illegal so I can only dream of having one up here (but that doesn't stop me from watching you guys at work and seeing how they turn out). One day I may travel with my wife and check them out in a country that allows them but until that day I have to settle on hearing your guys stories.

Regarding the suppressor, I will be sure to post some pictures when I am done. I have the end caps and 4 baffles finished. I just need to make 4 more baffles and thread the tube. Hopefully that will be finished up in the next week or two.

- Joined

- Jan 20, 2016

- Messages

- 602

I took apart the cross slide and compound for cleaning after about a month of use. I took some pictures if anyone is interested.

Here is the cross slide with the compound removed. I can't tell you what the discoloration in the middle there is but it didn't come off with scotch brite and it was covered in a layer of oil so that makes me think it isn't rust. You can see there that there doesn't appear to be a witness mark for the compound angle so once I figure out how to add one accurately, I will have to do so. You can see how the compound attaches with the t slots and nuts.

Here is the underside of the compound removed I was suprised to find that the motion screw was a standard 60 degree thread rather than an acme thread. The one on my HF was acme and I thought that was the standard. This could explain some of the troubles I have been having with it. I am having a hard time getting it to move smoothly without binding while still being tight enough to cut well. I don't think there is a way to convert this to an acme screw without making a new base for it so this will probably have to do for the forseeable future. You can also see the underside of the ways here. They aren't fantastic but they are good enough I think.

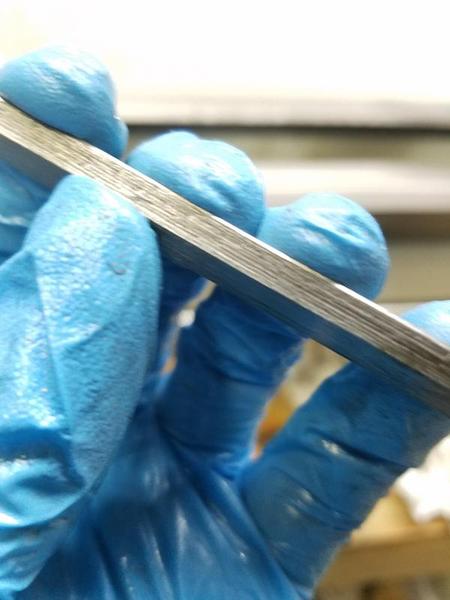

Now here is a problem. I had the hardest time focusing the camera on the finish for the compound gib but it looked like straight up tree bark. My glove would catch on it when I ran it over the top. This is on one of the sliding surfaces so that might explain some of the rough movement I was experiencing. This will certainly need some work. I may try to make one out of brass on my mill instead of trying to salvage this one.

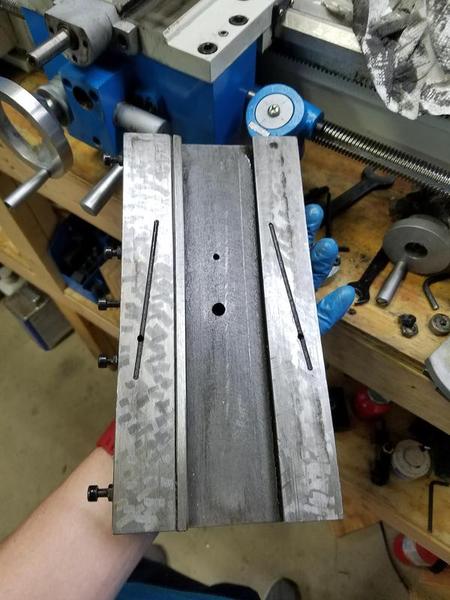

I popped the cross slide off as well and I was suprised by what I found. It appeared that the ways have been scraped on this one. I am no expert but this is what I thought that would look like. You can also see where the oilers deposit the oil on the ways. This gib was in much better condition. As a side note, there is about 20 thousanths of movement I can't seem to remove from the cross slide. It seems to be independant of the backlash and only results from direct force applied to the cross slide. If that is confusing, I will turn the dial towards me say 5 turns, then reverse direction several turns (backlash is most certainly taken up) then pull towards myself from the far end, and it will slip and than catch with about 20 thousandths of movement. I can then turn the dial the same direction and it continues without taking up any backlash.

Here is the carriage portion of the cross slide. Everything here seemed to be in good condition. This was before I cleaned everything up and as you can see there is some debris on the ways. I am not sure if it was there when the machine was running or if it was deposited as I removed the cross slide. Here you can see that there is an acme screw that the cross slide attaches to using a black and a bolt. I am wondering if the acme screw is not properly secured and it is causing that 20 thousandths of movement I can't seem to locate.

I am still having trouble with the gearboxes leaking oil. I will contact Matt about that again soon. They told me the gaskets sometimes take some time to seal so I should give it a few weeks and if it didn't stop, get back in touch and we would go from there.

Here is the cross slide with the compound removed. I can't tell you what the discoloration in the middle there is but it didn't come off with scotch brite and it was covered in a layer of oil so that makes me think it isn't rust. You can see there that there doesn't appear to be a witness mark for the compound angle so once I figure out how to add one accurately, I will have to do so. You can see how the compound attaches with the t slots and nuts.

Here is the underside of the compound removed I was suprised to find that the motion screw was a standard 60 degree thread rather than an acme thread. The one on my HF was acme and I thought that was the standard. This could explain some of the troubles I have been having with it. I am having a hard time getting it to move smoothly without binding while still being tight enough to cut well. I don't think there is a way to convert this to an acme screw without making a new base for it so this will probably have to do for the forseeable future. You can also see the underside of the ways here. They aren't fantastic but they are good enough I think.

Now here is a problem. I had the hardest time focusing the camera on the finish for the compound gib but it looked like straight up tree bark. My glove would catch on it when I ran it over the top. This is on one of the sliding surfaces so that might explain some of the rough movement I was experiencing. This will certainly need some work. I may try to make one out of brass on my mill instead of trying to salvage this one.

I popped the cross slide off as well and I was suprised by what I found. It appeared that the ways have been scraped on this one. I am no expert but this is what I thought that would look like. You can also see where the oilers deposit the oil on the ways. This gib was in much better condition. As a side note, there is about 20 thousanths of movement I can't seem to remove from the cross slide. It seems to be independant of the backlash and only results from direct force applied to the cross slide. If that is confusing, I will turn the dial towards me say 5 turns, then reverse direction several turns (backlash is most certainly taken up) then pull towards myself from the far end, and it will slip and than catch with about 20 thousandths of movement. I can then turn the dial the same direction and it continues without taking up any backlash.

Here is the carriage portion of the cross slide. Everything here seemed to be in good condition. This was before I cleaned everything up and as you can see there is some debris on the ways. I am not sure if it was there when the machine was running or if it was deposited as I removed the cross slide. Here you can see that there is an acme screw that the cross slide attaches to using a black and a bolt. I am wondering if the acme screw is not properly secured and it is causing that 20 thousandths of movement I can't seem to locate.

I am still having trouble with the gearboxes leaking oil. I will contact Matt about that again soon. They told me the gaskets sometimes take some time to seal so I should give it a few weeks and if it didn't stop, get back in touch and we would go from there.

It's always a good idea to go through the machine and do a good cleaning and inspection. There will probably be a few things that could be improved. On my 1127, I didn't like the way the VFD was mounted and ended up making a new mounting plate and cleaned up the wiring. I think I've also replaced most of the screws as well.

I need to pick up some wd40 and a spray bottle and start tearing it down then. New screws might be the first upgrade. Thanks for the heads up on the screws, I was hoping this wouldn't be like the mini lathes where all the screws were trash but it sounds like it is no better in that department.

- Joined

- Jan 20, 2016

- Messages

- 602

You are right. Initially I did a thorough cleaning and adjusted everything but not a complete disassembly. It has been working pretty well, and over time I have been taking it apart further and adjusting it better. I have been putting off leveling it which is probably a mistake. I am going to need to run a jack through the table and lift it up a bit as it looks like the left side is bowing just a bit to the weight. I am in no rush with it though and so far the limit to its precision seems to only be the amount of time I am willing to put into each operation. I think if I go slow enough, holding .0003" or tighter will be possible.It's always a good idea to go through the machine and do a good cleaning and inspection. There will probably be a few things that could be improved. On my 1127, I didn't like the way the VFD was mounted and ended up making a new mounting plate and cleaned up the wiring. I think I've also replaced most of the screws as well.

- Joined

- Jan 20, 2016

- Messages

- 602

Id say the first thing you get squared away is the change gears. The couplers deform very easily and jam up so they need to be a sliding fit. Tapping them in will only lead to trouble. Once you get the machine, I would put the square nuts in the chuck and polish them up to a nice mirror finish. Then do the same with the couplers until they are a solid sliding fit. Not loose, but I have found they don't wear well. If they are too tight, using force to try to fit them leads to trouble.Man, I appreciate the update just got my pm-1030v set up today and decided to check out the forums after two weeks of waiting on a table and people to lift it. Is there something I should investigate strait out of the box first?

Then take a file to the change gear key ways and use some sandpaper to open up the insides until the couplers fit well without being forced into place. If I spent 2 hours doing that, my first 2 4 hour gear changes would have been avoided.

- Joined

- Jan 20, 2016

- Messages

- 602

I just documented the baffles on silencertalk. Ill post a link in a sec if you are interested.Just curious on how the baffles are made?