Thanks Just for Fun.

I will keep an eye on the studs. At this point I'm watching everything.

I've searched almost daily for the reason the clutch wouldn't release and all I could find was something about it being an adjustable clutch. Not really sure what the adjustment does and neither does anyone else that I can find. I did run across one guy that pulled his clutch and rebuilt the engine and had a similar problem. He didn't say what he finally did to fix it.

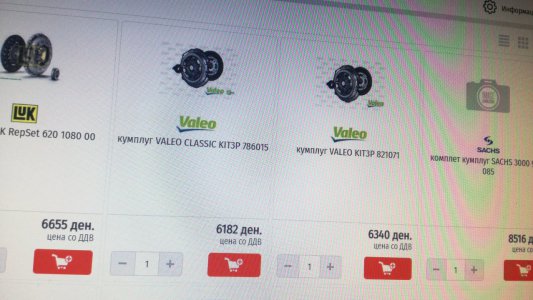

The car drives like I remember my other old cars drove. Feels stiff, steering is heavy. I've not done a panic stop yet to test the brakes but I probably should before I take it on the freeway to get the front end done. But when I pulled it back in the shop I could easily feather the clutch to move it a little bit to line up with my lift. Nice clutch, not cheap but nice. But I would have paid much more to fix the problem.

Now I have to replace the right hand window regulator. Great fun, not. I looked at the hood gaps today and the gap at the back of the hood it great, about 1/8". Left side gap is 1/8" all the way. But on the right close to the front it's 3/8" plus which means the fender had to come in, but no way to do that. The core support won't let it. I guess that's what I get for buying fenders and core support that weren't genuine GM parts. I'm not sure how to fix this, best I can figure is the core support needs to be cut and shortened and re-welded. And there is the problem of the hood hinge on the right side not coming down all the way. I can push it down into place, but have to do that every time.

Now I'm trying to make a decision what to work on next, my camaro or my 55. The camaro just needs an engine change (and I have a new engine) and a tune on the computer for the bigger engine. The 55 needs everything from the ground up. 55 is a multi year project, but I'd trade the nova and the camaro for a good 55 any day. I guess if I was smart (I'm obviously not) I'd get rid of all this old iron and just put my money in the bank as I make it.

But I've never been accused of being smart.

Dan, do me a favor.

keep a close eye on those 7/16 lug studs I tacked those nuts on.

they look a wee bit light duty for your application to me.

And if you are in CR area stop by, I’d love to see the Nova in person.

I will definitely make it a point of stopping by.