-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- GENERAL TYPES OF METALWORKING MACHINES

- ANTIQUE & VINTAGE MACHINERY

- MISC ANTIQUE & VINTAGE MACHINERY

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Micke's Vintage Bacho Lathe

- Thread starter Micke S

- Start date

- Joined

- Nov 27, 2015

- Messages

- 603

Definitely not the fun part. I'm thinking we should all have an appropriately attired, (3" heels and short-shorts) curvaceous and mute young shop bunny to do that kind of work.Mike

Here's my shop bunny, but it's in hibernation at the moment.

Micke, beautiful work!

Sent from my iPhone using Tapatalk

- Joined

- Feb 2, 2013

- Messages

- 3,628

very beautifully done, great looking machine!

- Joined

- Oct 9, 2014

- Messages

- 465

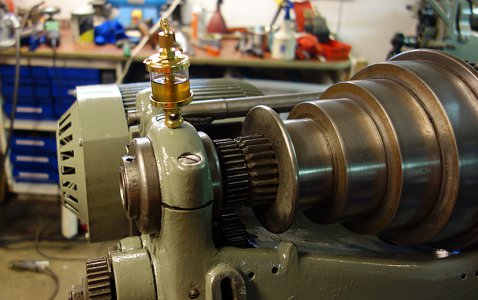

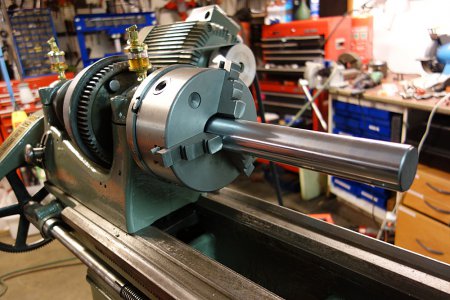

This is almost the end of the project. The Bahco lathe was tested today without remarks  I tested it up to 3000 rpm on the spindle and there are no vibrations. This rpm is too much I guess for normal operation with glide bearings, but I wanted to stress it a bit at this test.

I tested it up to 3000 rpm on the spindle and there are no vibrations. This rpm is too much I guess for normal operation with glide bearings, but I wanted to stress it a bit at this test.

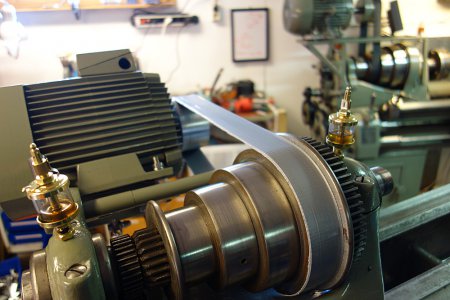

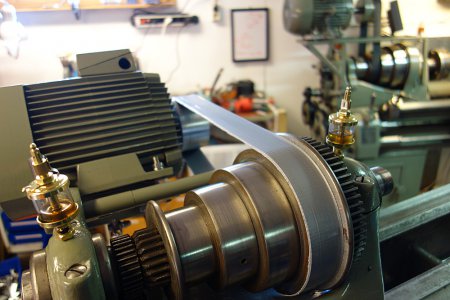

I haven't got the right drive belt yet so I used about 5 layers of 3M silver tejp as a temporary solution. I'm surprised how well it work. The inner layer was oriented up side down with some overlap.

I haven't got the right drive belt yet so I used about 5 layers of 3M silver tejp as a temporary solution. I'm surprised how well it work. The inner layer was oriented up side down with some overlap.

- Joined

- Dec 11, 2014

- Messages

- 891

Now that's a new use for Duct Tape I've never thought of.

Great job on the lathe.

I wish I had done the same to mine when I first got it, but I was anxious to make some chips.

I guess I'll do the clean and spit shine on the next one.

Great job on the lathe.

I wish I had done the same to mine when I first got it, but I was anxious to make some chips.

I guess I'll do the clean and spit shine on the next one.

Last edited:

- Joined

- Oct 9, 2014

- Messages

- 465