- Joined

- Jul 9, 2014

- Messages

- 613

David

I saw the 3 handled pliers, very neat, but I was referring to the shop made tool you spoke of in the first part of your message.

John.

John,

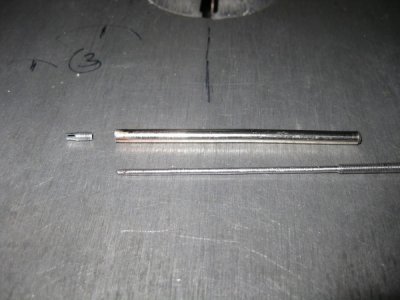

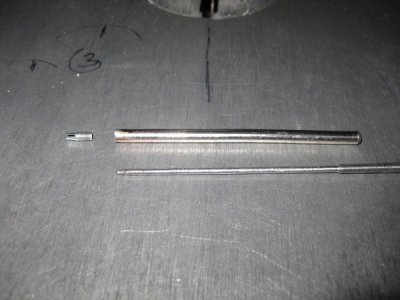

I hope to turn up one or two removers/ inserters for this type of clip once I get over the current flare up with my spinal problems. So far I have one partially done

What is the smallest tap & die set that you use?

I should have one of the smaller BA T&D sets but can't bend down enough to go rummaging through all my tool drawers.

When I used to repair photocopiers it got to be a PIA to take the clips off with pliers as like most folk are saying" Ping it's gone ..now is it inside the machine or not"

Putting them back on was usually done by turning up a 2 or 3" long cone / mandrel with a fine finish . Making it the same diameter as the bar the clip was to go on & give it a very slight counter sink at the major diameter end so it always sat well on the shaft , you simply put the clip on the cone , offered the cone up to the bar end and quickly slid the clip off the cone onto the bar , sometimes using a small piece of tube a bit bigger than the cones big end if you had to push the clip on a long way .