-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Impossible Retaining Rings

- Thread starter Franko

- Start date

- Joined

- Feb 24, 2015

- Messages

- 1,382

Thanks, Brav. I have a couple suppliers locally I can check with if that happens. I think the e-clips are going to be fine.

I have about a dozen of those stupid g-clips that I don't plan to ever use again.

It is possible someone makes small enough snap rings that would work, but I'll have to put an eyeball on them.

I have about a dozen of those stupid g-clips that I don't plan to ever use again.

It is possible someone makes small enough snap rings that would work, but I'll have to put an eyeball on them.

- Joined

- Mar 10, 2015

- Messages

- 248

If that is the same tool that LMS sells I bought replacement snap rings for it at Lowes, it had the same g-clips when it showed up. I think they were 1/4 inch.

- Joined

- May 4, 2015

- Messages

- 3,583

I would use the eclips and dispose of those g clips the real gclips are not that whimsy and cheap if the clips bend they are not any good . Spring steal used must have been scrap bike rim or some other recycled junk. Snap rings are pain enough , eclips are about the best for your application .

You didn't say anything about actually using the knurler. If you have used it and your results are like mine then you will stop worrying about those clips. This tool is so hopelessly flexible that I found it to be virtually useless. The knurl wheels don't track straight since the whole tool twists as soon as the wheels are engaged with the work. Sorry to be disparaging about your purchase or to the tool seller as they have some decent tools. This just isn't one of them in my opinion. A knurl tool which works for me is the home built version by Tom's Techniques.My new Shars scissor type knurling tool arrived today.

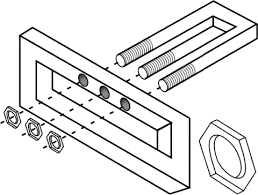

The dies are held on shafts secured with very small retaining rings I've never seen before.

I have three different kinds of retaining ring pliers and none of them could get a grip.

Is there an actual way to get them off without breaking them?

How the heck does one install them?

I did manage to remove them by breaking them, and I did have a set of rings that included the same type ring in the right size. I did manage to install them, but it was almost impossible. There must be a right way.

I think they are called G-type retaining rings.

View attachment 106687

- Joined

- Feb 24, 2015

- Messages

- 1,382

Kam, my first attempt did wander when I tried to tighten the knurls while the part was spinning. After some experimentation, I found that if I tightened the wheels while the chuck was not turning I got a much better result.

What worked for me was to tighten the knurls, then turn on the lathe at very low speed (about 60 rpm) for a couple turns. If I wanted the knurls deeper, just repeat the process. I came out with a pretty good knurl that way. This one was done in one pass.

What worked for me was to tighten the knurls, then turn on the lathe at very low speed (about 60 rpm) for a couple turns. If I wanted the knurls deeper, just repeat the process. I came out with a pretty good knurl that way. This one was done in one pass.

Last edited:

Must be some exotic steel. I used to have a pair of very small electronics needle nose that I ground down and left a small ridge on the tips. They worked good, but some rings still broke. I have an assortment of external and internal snap rings to replace them. If they are too small for that I usually go to the local hobby shop and look on the aircraft hardware section for them.

Never thought about a hobby shop but I bet some of those RC's would use them. Personally I could remove one and take the axle down to my local hardware store to find a good replacement. I am one of those who could see either type flying off into space, I am not a fan of that type of clips.

- Joined

- Jul 9, 2014

- Messages

- 613

Next time you have the G clips and no three legged circlip pliers with the full set of interchangeable legs, turn up a simple bar where the end is just big enough to slip in the gap of the clip . Drill the bar with a clearance hole for a long bolt you have that you have & turn the head down to make a cone. counter bore the bar to loosely fit the cone on the end of the bolt & give the turned bar/sleeve a split skirt with a fine hacksaw blade .

Tapping the pin with the clip on so that the pin is not trapping the clip against the host body is a must , even a slight grip / nip will see the clips break like yours did .

Now all you need to do is put the turned bolt in the bar at the cone end, slip the bar in the G clip , put a nut on the bolt . Then gently tighten it up ,the cone in the lightly counter bored hole will expand the sleeve, the jaws will grip the clip & open up the clip .

Three legged circlip pliers are not cheap but one set with all the different ends will last you a life time as the tips are renewable

I use to have a set till some thieving scrote broke into my man cupboard and waltzed of with five big tool boxes of quality tools ( Mainly ex USAF aircraft stuff from a USAF base close down auction .

" www.buckandhickman.com/find/keyword-is-VLC/sort-is-Price+(Descending " is what I'm talking about .

Tapping the pin with the clip on so that the pin is not trapping the clip against the host body is a must , even a slight grip / nip will see the clips break like yours did .

Now all you need to do is put the turned bolt in the bar at the cone end, slip the bar in the G clip , put a nut on the bolt . Then gently tighten it up ,the cone in the lightly counter bored hole will expand the sleeve, the jaws will grip the clip & open up the clip .

Three legged circlip pliers are not cheap but one set with all the different ends will last you a life time as the tips are renewable

I use to have a set till some thieving scrote broke into my man cupboard and waltzed of with five big tool boxes of quality tools ( Mainly ex USAF aircraft stuff from a USAF base close down auction .

" www.buckandhickman.com/find/keyword-is-VLC/sort-is-Price+(Descending " is what I'm talking about .

Last edited:

- Joined

- Feb 24, 2015

- Messages

- 1,382