- Joined

- Oct 8, 2014

- Messages

- 127

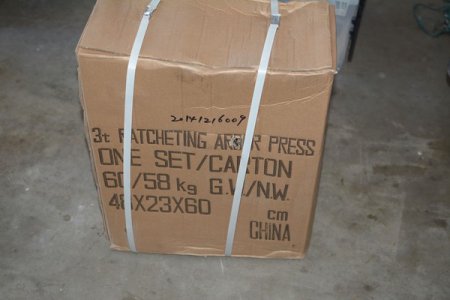

My press arrived today, strapped to a pallet & on a truck with a liftgate. Piece of cake to wheel off & then move to the hand truck.

Here's what my box looked like, must be cause I'm closer to China

So far so good

Now to get busy building something to mount it to. Well, maybe next rainy day. Hear the beckon of the rifle range.................

Mark

Here's what my box looked like, must be cause I'm closer to China

So far so good

Now to get busy building something to mount it to. Well, maybe next rainy day. Hear the beckon of the rifle range.................

Mark

It needs to be bolted to the floor too but I'm not sure where it is going to end up, I may just add some angle out the front with a platform then all the force is contained in the frame.

It needs to be bolted to the floor too but I'm not sure where it is going to end up, I may just add some angle out the front with a platform then all the force is contained in the frame.