- Joined

- Jan 21, 2013

- Messages

- 872

Very nice work there Joe!

Very nice work there Joe!

Wish I would have found that one about 2 weeks ago. I am right in the middle of soldering up a pcb for a Yadro.

Hi from across the pond,

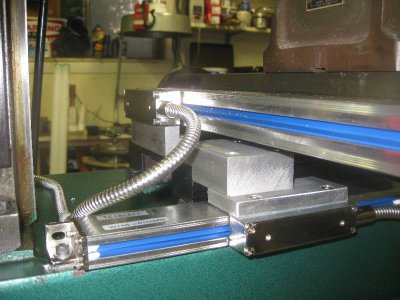

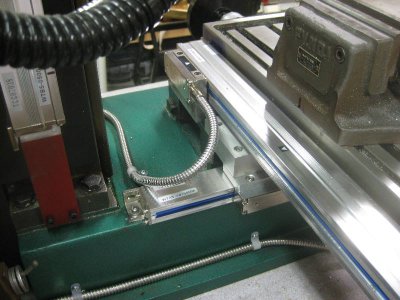

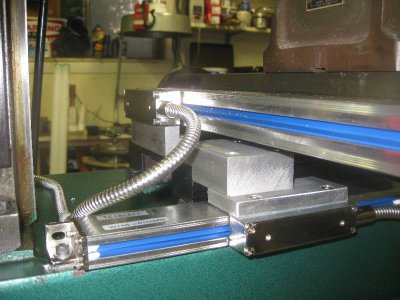

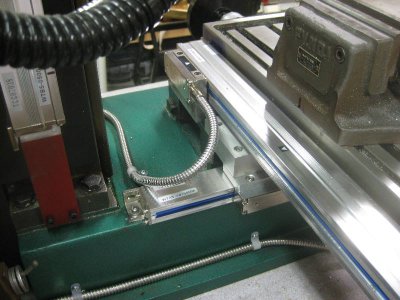

For what it's worth I would steer clear of the PC based system; I have just fitted a X & Y axes set up on my WM16 (US equiv' Grizzly 0704/BF20L) & the UK version I bought is the iguage system equiv' that you guys have in the states, & at a reasonable pice too £67.50.. $100.77 (at todays exch' rate). I have fitted the remote readouts in a convenient spot for me & have just used it for the first time this week..what a boon they are! just set up my datum point ..zero the readout & machine to required length/width.. job done.. no longer have to rely on the handwhheel dials :winner:, have a look at pics.. have since attached aluminium angle to protect the X axis.

Regards & have fun

George

I am a home shop user.

I basically only use the Digital Calipers I adapted to my machines to get me close a finished depth of cut, and then put my attention on the hand wheels to finish the cut.

I haven't had the need to use fluid splashing everywhere to get done what I do, so I have not had issues with debris or fluids. No skipping or anything.

As far as I know, you can even cut the Rule section down to the length you want, and they still operate! But I haven't tried this.

I adapted a few actual digital calipers to my machines. ***** to drill through them, which i did, but there are easier ways to attach them.

I am interested in these iGage units Jim Shroeder mentioned to complete my machines, as they are already set up and ready to mount- and so affordable! Same price as cheap-y calipers!

Bernie

I was just thinking about a pc based DRO but heard there was a lot of latency in them. I need a dro really bad for my mill. I could live with the Igauging ones on my lathe but want a better system on my mill.

If there was an Android DRO it might look like this http://www.yuriystoys.com/search/label/DIY DRO Project.

Hey, a New Jersey buddy! Bernie, you can get the Igaging units from Grizzly. Check the link I have in my previous post.

If there was an Android DRO it might look like this http://www.yuriystoys.com/search/label/DIY DRO Project.