- Joined

- May 7, 2023

- Messages

- 1,341

Tasty tasty meteor......that pizza looks like a meteor.

Tasty tasty meteor......that pizza looks like a meteor.

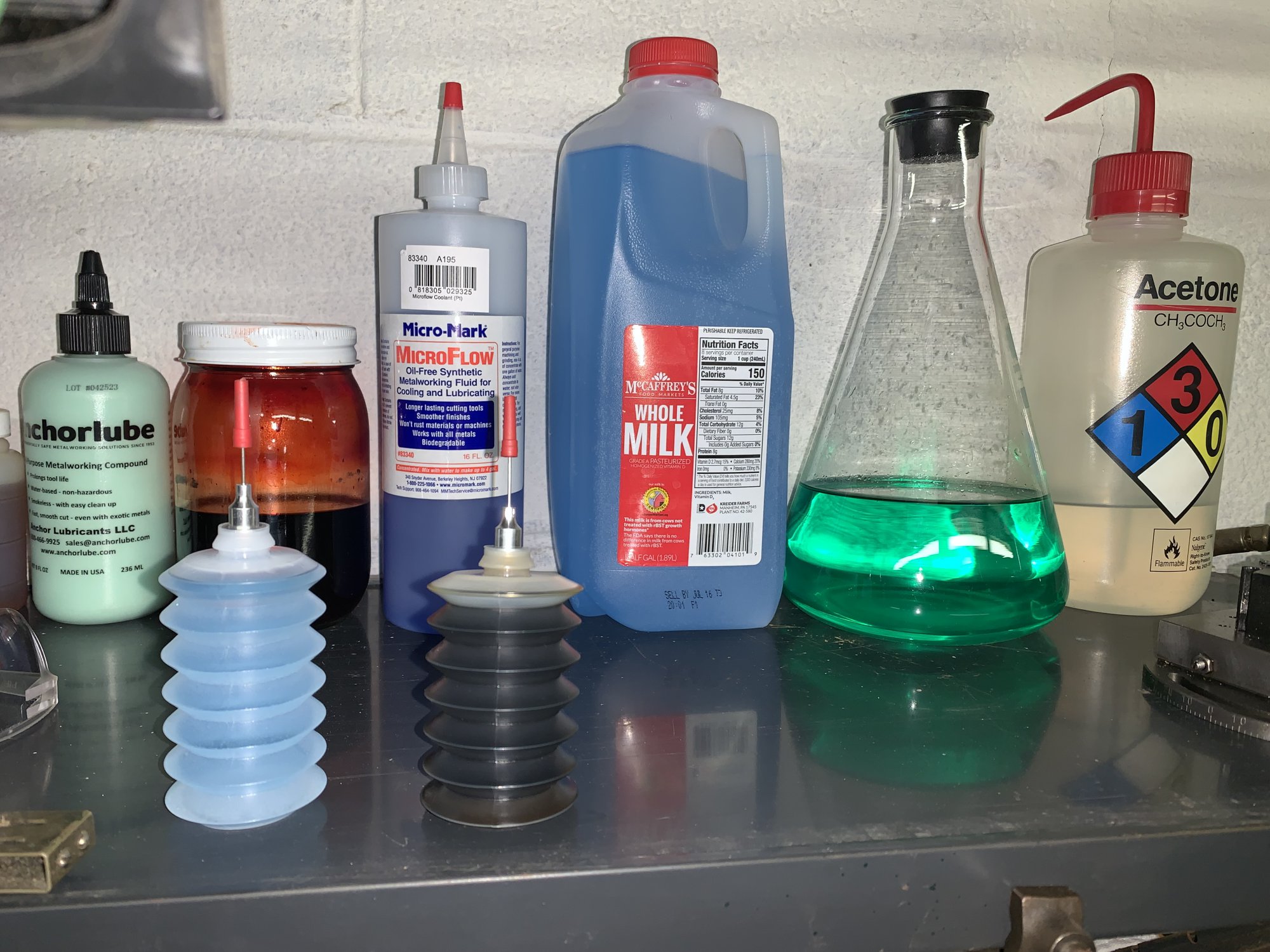

Get yourself some needle tip bellows applicators go your cutting fluids and coolant.

It saves on fluids as you only put it where you want it and as a bonus there’s less mess to clean up.

At work I’ll just blast whatever I’m working on with WD-40 and if it gets all over the mill it’s no big deal.

But at home where I’m paying for the fluids and have a real possibility of tracking them into the living quarters this is a big help on both fronts.

You can get that needle right into the flutes of day a tap you’re using verses all over the surface of the part hoping it will get where it’s needed.

There’s actually two in this pic if you look, one is the micro mark cutting fluid diluted as per instructions and the other is really old WD-40 that would not come out of the can as it lost pressure.

Why it turned black is beyond me, but it still works OK.

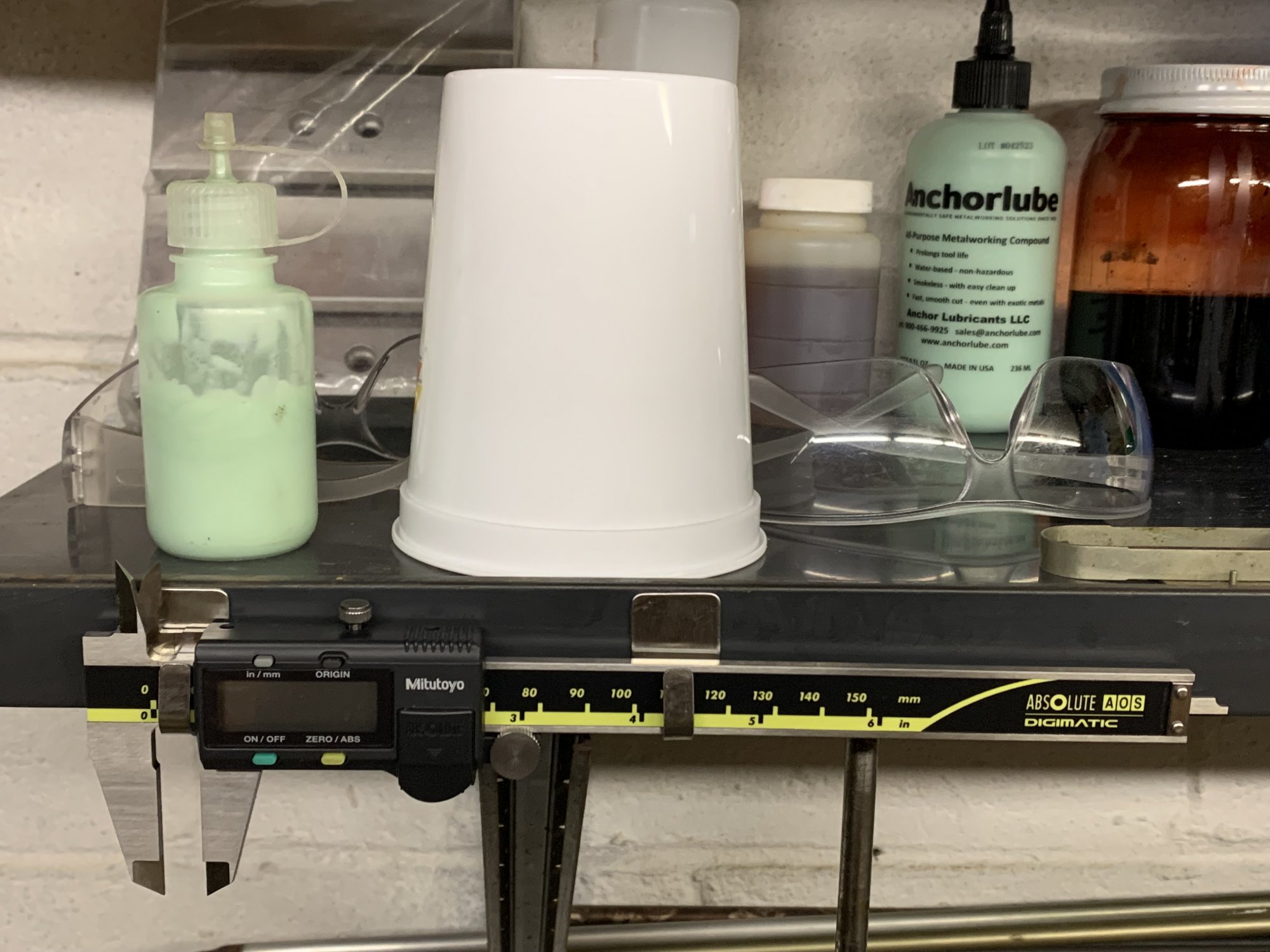

Another thing I find invaluable is to make a caliper rack to hang your calipers on.

Gets them up and out of the way and you don’t have to search for them.

I solved that problem with this particular bottle by poking the cap with a hot needle making the tiniest hole in the down tube so it can breathe a little. I have to really squeeze to get the juice to come out, but then again it vents to atmosphere freely a little so it doesn't do like you described.One comment related to @RaisedByWolves first picture.

The type of squeeze bottle, shown in the first picture labeled Acetone, can be a PITA.

The problem is, if they are subjected to temperature change, they will pump out the some of the contents.

The spout tube extends down very close to the bottom so it's always under the fluid level. When the volume of air inside the bottle is warmed, it expands and displaces some fluid out the spout. When the air cools the bottle may draw in more air so the cycle repeats until the fluid level drops below the bottom of the tube.

You need to be conscious of the compatibility/damage the fluid may do to the surface(s) where that type of bottle is stored and used.

A tiny vent hole is a pretty good idea. It would be easy enough to put a finger tip over the vent hole when squeezing. A tiny hole wouldn't allow much evaporation.I solved that problem with this particular bottle by poking the cap with a hot needle making the tiniest hole in the down tube so it can breathe a little. I have to really squeeze to get the juice to come out, but then again it vents to atmosphere freely a little so it doesn't do like you described.

My Total boat jug of epoxy is a different story.

The hole I made goes to the inside so the squeezins only go back inside and it doesn't need plugged off.A tiny vent hole is a pretty good idea. It would be easy enough to put a finger tip over the vent hole when squeezing. A tiny hole wouldn't allow much evaporation.