- Joined

- Mar 21, 2018

- Messages

- 1,597

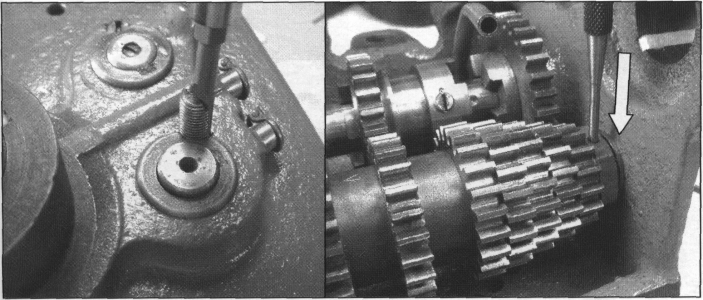

Any idea why the 24t gear is the only gear that’s got wear? Maybe the lathe was used for one single operation for a long time.

That's not unheard of. They weren't purchased as hobby lathes, but usually for a specific purpose. What does the pinion gear look like?