- Joined

- Feb 17, 2013

- Messages

- 4,406

@Pcmaker - here are some some dimensions for you to be aware of. They're from my own recently delivered PM835S:

Pallet height 8", width 48", depth 48"

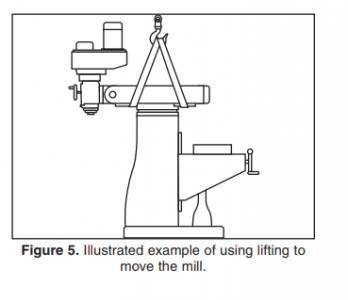

The center of the "loop" of the lifting eye atop the ram is about 69" above the bottom of the mill.

This means that the hook of your engine hoist must be capable of lifting from a point 69+8=77" above the ground. When I uncrated my mill, I looked at the height required and knew that my 2 ton engine hoist was NOT going to do the job.

Pallet height 8", width 48", depth 48"

The center of the "loop" of the lifting eye atop the ram is about 69" above the bottom of the mill.

This means that the hook of your engine hoist must be capable of lifting from a point 69+8=77" above the ground. When I uncrated my mill, I looked at the height required and knew that my 2 ton engine hoist was NOT going to do the job.