- Joined

- Dec 18, 2013

- Messages

- 2,012

Re: FOUR JAW CHUCK do like it or hate it 4

Okay I did some quick research on them...ugh it does seem the 6 jaw is a specialty chuck with some serious issues especially if the stock is not true. I think I will look at a higher quality 3 jaw chuck to replace my CHINA chuck and some soft jaws. As for an 8 inch chuck...yeah D1-5 has that covered though I will check the clearance.

Do you work with a lot of thin wall materials? You do know that there are more disadvantages to a 6-jaw over a 3-jaw than advantages right? Most people don't know that. Just want to point that out before you spend so much on one, many would not be happy with the disadvantages. But they sure are purdy.

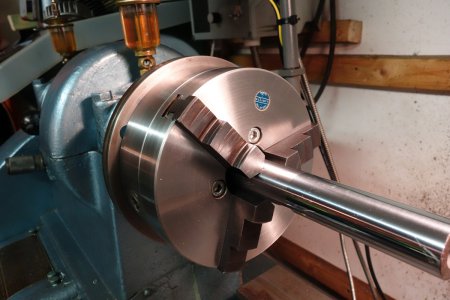

IMO an 8" is a pretty hefty chuck for a 12x36, I personally wouldn't want that big of a scroll chuck, the 4-jaw independent is fine. Be sure to check if the jaws will clear the ways when fully extended.

Okay I did some quick research on them...ugh it does seem the 6 jaw is a specialty chuck with some serious issues especially if the stock is not true. I think I will look at a higher quality 3 jaw chuck to replace my CHINA chuck and some soft jaws. As for an 8 inch chuck...yeah D1-5 has that covered though I will check the clearance.