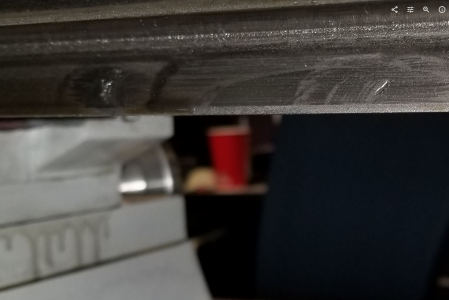

I would fill it with JB Weld and carefully finish it flush, chips could lodge in it and cut the saddle when it is run over the hole.

I would be concerned that the JB Weld might wear the gibs differently than the cast iron over time. I am not sure if this would be an issue or not.

As the machine is new it might be a better option for me to deal with it via warranty.