I found an old Century motor book telling how to wire it for 220/110. According to that the motor is wired for 110v now which makes sense because of the 110v cord that is wired into the motor. I don't have any way of telling for sure what the 4 legs are numbered because there are no # tags on the leads. I'm just assuming that they are connected correctly because it's been wired this way for a long, long time. I'm just having trouble figuring out how it worked the way the cords are wired.tried replying from my phone but it wouldn't..

That's a repulsion motor if it has brushes.

I don't know a thing about them.

the tag says both repulsion and induction repulsion for start, induction for run... not even going to try on this one.

Mark may be able to help.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Found this old South Bend lathe and it followed me home

- Thread starter olddude

- Start date

I've been sitting here for a while thinking and wondering if I even need a reverse on this lathe anyway or if it ever had a reverse on it to begin with. In one of the Century books I looked at it said there was a reversing, repulsion induction motor where the motor could be reversed using a # 791 drum switch but I didn't see any direction for wiring it. Someone out there must have this same motor on their lathe just gotta find out who.

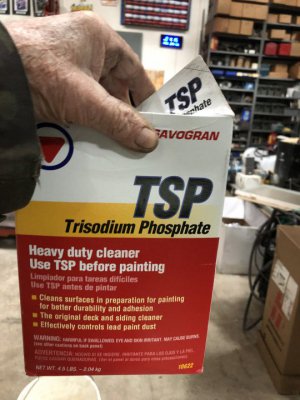

Hey Woodchucker, I've got this thing pretty much all apart and was wondering how you did your number plates when you soaked the gear box in TSP and Evapo-rust? Where did you find your Evapo-rust, What I have seen is pretty expensive for a gal and I'm thinking it would take quite a bit to cover the whole bed. I've been looking for some kind of container that it would fit tightly in with no luck. I have an old truck tool box I was going to soak all the parts in at once but it would probably take 25 gal to cover the bed.

I went out and picked up 3 gal's of kerosene at $5.22 a gal to use to get the bulk of the dirt, grime, grease off the parts and that worked pretty good and it seems to do a pretty good job of keeping them from flash rust. I'm thinking that I'll wait and take the gear box and headstock apart one at a time once the other parts are done to help keep that stuff together. I've just about run out of tabletop space for all this stuff.

I went out and picked up 3 gal's of kerosene at $5.22 a gal to use to get the bulk of the dirt, grime, grease off the parts and that worked pretty good and it seems to do a pretty good job of keeping them from flash rust. I'm thinking that I'll wait and take the gear box and headstock apart one at a time once the other parts are done to help keep that stuff together. I've just about run out of tabletop space for all this stuff.

It's not the cheapest stuff in the world but you can re-use it a bunch of times so it represents good value. There are techniques to large parts like you can put evaporust soaked towels or similar on large surfaces and it will do the job.Hey Woodchucker, I've got this thing pretty much all apart and was wondering how you did your number plates when you soaked the gear box in TSP and Evapo-rust? Where did you find your Evapo-rust, What I have seen is pretty expensive for a gal and I'm thinking it would take quite a bit to cover the whole bed. I've been looking for some kind of container that it would fit tightly in with no luck. I have an old truck tool box I was going to soak all the parts in at once but it would probably take 25 gal to cover the bed.

I went out and picked up 3 gal's of kerosene at $5.22 a gal to use to get the bulk of the dirt, grime, grease off the parts and that worked pretty good and it seems to do a pretty good job of keeping them from flash rust. I'm thinking that I'll wait and take the gear box and headstock apart one at a time once the other parts are done to help keep that stuff together. I've just about run out of tabletop space for all this stuff.

Well I don't know if I'll ever get this thing back together but 1 of the big three parts is all apart and somewhat cleaned up. I have the apron casting soaking in TSP now but I need to go out and get another tank of gas to clean the rest of the other parts. Everything looked pretty god except the clutch knob. It has a crack on the inside bearing surface that run all the way across. I didn't take a pic but I will when I get back out there.

I rigged up a soak tank out of one of those little 30lb oil drums by cutting the top out. I had an old turkey fryer that I loaned to someone that came back with a hole in the bottom of the pot but I kept the burner and that small drum fit on it very nicely. I put the top that I cut out in the bottom of the drum to help keep the heat from the burner off the parts. I put the two bed legs in first for my parts backet to sit on and I still had room to hang a few larger parts in there also. Once the parts were in the drum ten gallons of the TSP solution filled the drum just enough to cover the basket.

I ran out of gas before the first batch was done but I just left them in the tank overnight, hopefully they will be alright. I didn't have time to get many pics but I'll post what I have for now. The third and forth pic are the parts after a kerosene bath the last one is a batch after they came out of the TSP. That stuff works pretty good cleaning the parts and what paint that is left scrapes off fairly easy after only a couple hours in the boiling bath.

I rigged up a soak tank out of one of those little 30lb oil drums by cutting the top out. I had an old turkey fryer that I loaned to someone that came back with a hole in the bottom of the pot but I kept the burner and that small drum fit on it very nicely. I put the top that I cut out in the bottom of the drum to help keep the heat from the burner off the parts. I put the two bed legs in first for my parts backet to sit on and I still had room to hang a few larger parts in there also. Once the parts were in the drum ten gallons of the TSP solution filled the drum just enough to cover the basket.

I ran out of gas before the first batch was done but I just left them in the tank overnight, hopefully they will be alright. I didn't have time to get many pics but I'll post what I have for now. The third and forth pic are the parts after a kerosene bath the last one is a batch after they came out of the TSP. That stuff works pretty good cleaning the parts and what paint that is left scrapes off fairly easy after only a couple hours in the boiling bath.

Attachments

I mis-spoke yesterday when I said that the clutch knob had a crack in it. It was the tail stock screw nut that had the crack I guess sniffing to many TSP fumes will clog ya brain. I got half the bed cleaned and I flipped it around to the other end before I left last night so that end could get a head start for today. I'll have to wire brush the bed to get all the old paint off because I can't get it in my sand blast cabinet but most of it will come off by just scrubbing it with a Brisiel brush so I should be able to get it paint free without to much trouble. Most of the gears that I have come across have cleaned up pretty good by soaking them in kerosene and then hitting them with a small wire brush. There are a few stains in places that are a little hard to deal with but I'm not to worried about them because they are just stains and not pitting or other damage. This is a slow process; it probably wouldn't be so bad if I had room for all these parts and it's hard to keep them all together. I'm thinking I'll paint and put back together what I have torn down now then move on to the headstock, gear box, chucks and other pieces later.

I got half the bed cleaned and I flipped it around to the other end before I left last night so that end could get a head start for today. I'll have to wire brush the bed to get all the old paint off because I can't get it in my sand blast cabinet but most of it will come off by just scrubbing it with a Brisiel brush so I should be able to get it paint free without to much trouble. Most of the gears that I have come across have cleaned up pretty good by soaking them in kerosene and then hitting them with a small wire brush. There are a few stains in places that are a little hard to deal with but I'm not to worried about them because they are just stains and not pitting or other damage. This is a slow process; it probably wouldn't be so bad if I had room for all these parts and it's hard to keep them all together. I'm thinking I'll paint and put back together what I have torn down now then move on to the headstock, gear box, chucks and other pieces later.

I got half the bed cleaned and I flipped it around to the other end before I left last night so that end could get a head start for today. I'll have to wire brush the bed to get all the old paint off because I can't get it in my sand blast cabinet but most of it will come off by just scrubbing it with a Brisiel brush so I should be able to get it paint free without to much trouble. Most of the gears that I have come across have cleaned up pretty good by soaking them in kerosene and then hitting them with a small wire brush. There are a few stains in places that are a little hard to deal with but I'm not to worried about them because they are just stains and not pitting or other damage. This is a slow process; it probably wouldn't be so bad if I had room for all these parts and it's hard to keep them all together. I'm thinking I'll paint and put back together what I have torn down now then move on to the headstock, gear box, chucks and other pieces later.

I got half the bed cleaned and I flipped it around to the other end before I left last night so that end could get a head start for today. I'll have to wire brush the bed to get all the old paint off because I can't get it in my sand blast cabinet but most of it will come off by just scrubbing it with a Brisiel brush so I should be able to get it paint free without to much trouble. Most of the gears that I have come across have cleaned up pretty good by soaking them in kerosene and then hitting them with a small wire brush. There are a few stains in places that are a little hard to deal with but I'm not to worried about them because they are just stains and not pitting or other damage. This is a slow process; it probably wouldn't be so bad if I had room for all these parts and it's hard to keep them all together. I'm thinking I'll paint and put back together what I have torn down now then move on to the headstock, gear box, chucks and other pieces later.Attachments

This is a slow process; it probably wouldn't be so bad if I had room for all these parts and it's hard to keep them all together. I'm thinking I'll paint and put back together what I have torn down now then move on to the headstock, gear box, chucks and other pieces later.

The guys that take everything apart at once are impressive to me. I couldn't do it either because of space limitations but I wasn't tempted because I wasn't painting mine. I just wanted it to work so I could start using it.

Well I'm probably sell this one once I get it done and wanted to make sure everything is ok before I did. I really haven't found much wrong with it yet other than the cracked tail stock screw nut. There's very little wear that I've seen so far. I have several different coating kits that I can use to paint it with and I think I'm going with a product called Carbothane 134 HG. It's a two-part polyurethane based industrial paint with good chemical resistance, it's a very hard durable, chip resistant finish. It also has stain resistant properties and easy to clean and doesn't need a primer is a direct on metal finish. The best part is I have several of these kits that are just the right color.

- Joined

- Nov 25, 2015

- Messages

- 8,301

sorry, for some reason notifications are failing for me. I am not seeing many messages to me.Hey Woodchucker, I've got this thing pretty much all apart and was wondering how you did your number plates when you soaked the gear box in TSP and Evapo-rust? Where did you find your Evapo-rust, What I have seen is pretty expensive for a gal and I'm thinking it would take quite a bit to cover the whole bed. I've been looking for some kind of container that it would fit tightly in with no luck. I have an old truck tool box I was going to soak all the parts in at once but it would probably take 25 gal to cover the bed.

I went out and picked up 3 gal's of kerosene at $5.22 a gal to use to get the bulk of the dirt, grime, grease off the parts and that worked pretty good and it seems to do a pretty good job of keeping them from flash rust. I'm thinking that I'll wait and take the gear box and headstock apart one at a time once the other parts are done to help keep that stuff together. I've just about run out of tabletop space for all this stuff.

I used TSP on my gear box. I did not use evapo rust on it. Instead I soaked it either in mineral spirits or wd 40. I think I used MS for that unit. as it will prevent flash rust as well.

I get my evapo rust at tractor supply. last time it was $17 a gal. Right now, I need another gal, my old gal finally did it's last piece and won't work anymore. It did quite a lot of metal.

- Joined

- Nov 25, 2015

- Messages

- 8,301

I'm not sure if you are sand blasting your carriage, cross slide, apron???? you don't want to unless you protect all the machined surfaces. if you blast the machined surfaces she's done. it will be too rough for use.

You should be able to source that tailstock nut on ebay, or make one.

You should be able to source that tailstock nut on ebay, or make one.