Well, ran the first test as everything is in, mounted and polished. The problem I'm having must have something todo with the config.H file. I ran 8 TPI and the score marks are pretty much touching each other, looks more like a rough finish pass than threading. Here my config settings (keeping in mind I have the same lathe as Clough and the exact same encoder/stepper-servo.)

Thoughts?

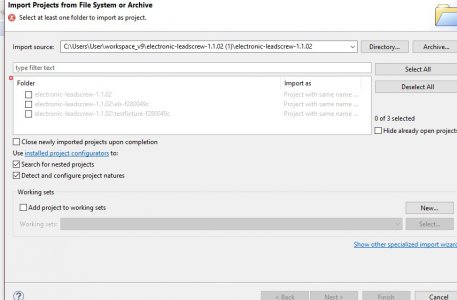

#ifndef __CONFIGURATION_H

#define __CONFIGURATION_H

//================================================================================

// LEADSCREW

//

// Define the type and pitch of leadscrew you have in your lathe. If you have an

// imperial leadscrew, define LEADSCREW_TPI. If you have a metric leadscrew,

// define LEADSCREW_HMM (pitch in hundredths of a millimeter). Do not define

// both.

//================================================================================

// For Imperial leadscrews: pitch in Threads Per Inch (TPI)

#define LEADSCREW_TPI 12

// For metric leadscrews: pitch in hundredths of a millimeter (HMM)

// Example: 200hmm = 2mm

//#define LEADSCREW_HMM 200

//================================================================================

// STEPPER/SERVO

//

// Define the number of steps and microsteps for your stepper motor, the pin

// polarity of the driver, and whether to use additional features, like servo

// alarm feedback.

//

// NOTE: If you are using a servo drive with something other than a 1:1 drive

// ratio, you can use the STEPPER_MICROSTEPS to compensate. For example, if you

// have a servo configured for 1000 steps/revolution and it drives the leadscrew

// through a 3:1 reduction, you can set STEPPER_RESOLUTION to 1000 and

// STEPPER_MICROSTEPS to 3.

//================================================================================

// Steps and microsteps

#define STEPPER_MICROSTEPS 1

#define STEPPER_RESOLUTION 1000

// Step, direction and enable pins are normally active-high

// #define INVERT_STEP_PIN true

#define INVERT_DIRECTION_PIN true

#define INVERT_ENABLE_PIN true

#define INVERT_ALARM_PIN true

// Enable servo alarm feedback

#define USE_ALARM_PIN

//================================================================================

// ENCODER

//

// Define the type of encoder you are using on the spindle. The firmware assumes

// the encoder is turning at a 1:1 ratio with the spindle.

//

// NOTE: the firmware is concerned with the quadrature edge count, which is

// four times the number of pulses. For example, if you have a 1024 P/R

// encoder, you need to enter 4096 here.

//================================================================================

// Encoder resolution (counts per revolution)

#define ENCODER_RESOLUTION 4096

// Which encoder input to use

#define ENCODER_USE_EQEP1

//#define ENCODER_USE_EQEP2

//================================================================================

// CALCULATIONS

//

// Define how calculations should be performed. Most users will not need to

// touch these settings.

//================================================================================

// Use floating-point math for gear ratios

#define USE_FLOATING_POINT

//================================================================================

// HARDWARE

//

// Define which hardware you're using:

//

// 1 - LaunchXL F280049C with ELS BoostXL v1

// 2 - LaunchXL F280049C with ELS BoostXL v2

//================================================================================

// See hardware version table above

#define HARDWARE_VERSION 2

//================================================================================

// CPU / TIMING

//

// Define the CPU clock, interrupt, and refresh timing. Most users will not need

// to touch these settings.

//================================================================================

// Stepper state machine cycle time, in microseconds

// Two cycles are required per step

#define STEPPER_CYCLE_US 5

// User interface refresh rate, in Hertz

#define UI_REFRESH_RATE_HZ 100

// RPM recalculation rate, in Hz

#define RPM_CALC_RATE_HZ 10

// Microprocessor system clock

#define CPU_CLOCK_MHZ 100

#define CPU_CLOCK_HZ (CPU_CLOCK_MHZ * 1000000)

#endif // __CONFIGURATION_H