Short version:

Tozguy is spot on. Replace the 51T gear with a 54T gear and you will get Imperial threads so close to perfect you won’t know the difference. Without altering the gear box or the leadscrew.

Long version:

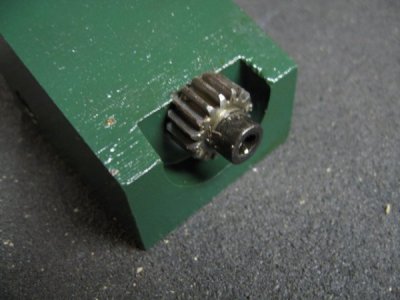

When the metric leadscrew (3mm pitch) was replaced with an Imperial leadscrew (8 TPI = 3.175mm pitch), the carriage moved farther for each revolution of the leadscrew than it did originally, which means it also moved farther for each revolution of the spindle than it did originally. To correct that error, the original 34T gear was replaced with a 32T gear to slow the leadscrew down when cutting metric threads. With the 32T gear, the 3mm gear box setting actually results in a 2.988 mm thread. The 1mm setting will produce a 0.996 mm thread. And so on. Plenty close enough for government work.

The original 51T gear hasn't been changed, hence the lathe still cuts Imperial threads with too much pitch. To get it back on track for Imperial threads, you need to replace the 51T gear with a 54T gear. That will result in a thread with so little error that it’s practically immeasurable. Something like 15.99+ TPI for the 16 TPI gear box setting.

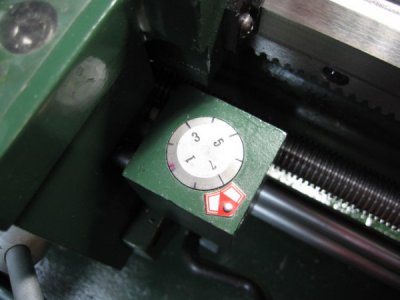

I think the thread dial, as is, will be useless for both metric and Imperial. You might cut an 8T or 16T gear and get it to work for Imperial threads, but I think you're stuck with leaving the half nuts engaged to cut metric threads.

Tom