- Joined

- Oct 31, 2016

- Messages

- 2,645

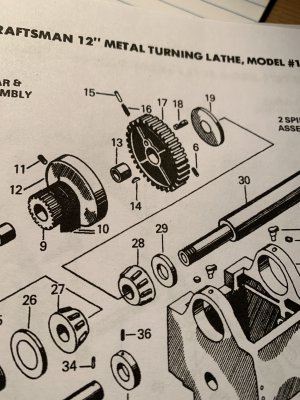

If belts are not loose, loosen the belts so everything can spin without trying to spin the motor. If the back gear is not engaged will the bull gear spin? And will the spindle spin? They should spin independent of each other since the lock pin is in the out position. When you engage the back gear and with the belts loose you should be able to easily spin the spindle and the bull gear should spin at a much reduced rate compared to the spindle. If you can't spin the spindle with the back gears engaged then the back gears are probably frozen on their shaft. I just checked this on my lathe. With the belt loose and the back gear engaged I could easily spin the spindle and the bull gear spun at a reduced rate.