My complete tear down has slowed a bit. I'm running out of places to put parts while I work on everything. I did get my parts washer up and running however. This thing is great. I'm glad I spent the money on it. I took Sharon's advice and did not get the crappy plastic HF model. I found one of equal size but with all steel construction. I'd recommend it to anyone with limited space: http://www.amazon.com/dp/B000OUXAE4/ref=pe_175190_21431760_M2T1_ST1_3p_dp_1

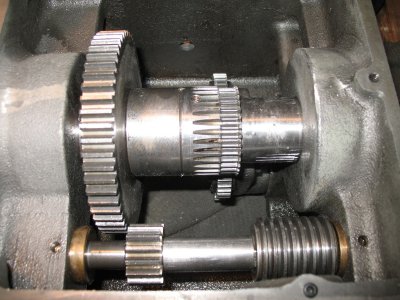

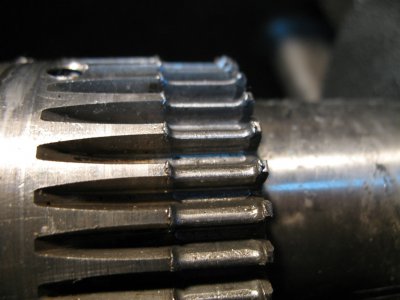

I've also come to a complete halt on disassembling the head stock. I can't seem to remove the hub from the spindle. In the exploded parts diagram it would seem that the only thing holding it onto the spindle is a set screw. I've already backed that set screw out. I have a feeling the hub is just stuck on due to gunk and grime. I've been spraying it with PB blaster. There is no good way to attach a gear puller either, since the spindle is hollow, and I really don't want to do anything that may cause damage to any portion of the headstock, so I'm going about this as gently as I can.

Any hints on how to remove this stubborn hub? I wouldn't doubt that once I get the hub off some other headstock parts will be stuck as well, but I can't move on till I get this off.

I've also come to a complete halt on disassembling the head stock. I can't seem to remove the hub from the spindle. In the exploded parts diagram it would seem that the only thing holding it onto the spindle is a set screw. I've already backed that set screw out. I have a feeling the hub is just stuck on due to gunk and grime. I've been spraying it with PB blaster. There is no good way to attach a gear puller either, since the spindle is hollow, and I really don't want to do anything that may cause damage to any portion of the headstock, so I'm going about this as gently as I can.

Any hints on how to remove this stubborn hub? I wouldn't doubt that once I get the hub off some other headstock parts will be stuck as well, but I can't move on till I get this off.