- Joined

- Jan 21, 2021

- Messages

- 48

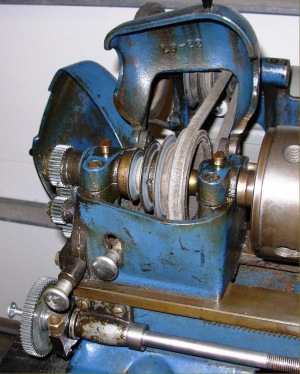

As I was re-assembling the carriage I noticed that the Carriage Traverse Gear Bearing was completely worn. There was almost 1/8" total play at the rack pinion end. The location of the oil hole under the carriage (and not exactly accessible) likely contributed to the wear.

As with the tumbler arm, I bored out the worn bearing and inserted a steel plug. This was then bored to match the dimensions of the Carriage Traverse Pinion shaft and the oil hole redrilled. No more slop and good for another 80 years.

Finished assembly.

Cheers,

Adrian

As with the tumbler arm, I bored out the worn bearing and inserted a steel plug. This was then bored to match the dimensions of the Carriage Traverse Pinion shaft and the oil hole redrilled. No more slop and good for another 80 years.

Finished assembly.

Cheers,

Adrian