-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

- Forums

- THE PROJECTS AREA

- PROJECT OF THE DAY --- WHAT DID YOU DO IN YOUR SHOP TODAY?

- Project of the Day Mega-Thread Archives

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2016 POTD Thread Archive

- Thread starter sanddan

- Start date

- Joined

- Feb 24, 2015

- Messages

- 1,382

I got a new basic tool for my shop I've been wanting for a while. I have a 7 x 12 horizontal bandsaw, but it isn't useful for cutting small and thin stock. The small vertical bandsaw cuts small stock ok, but it is not very accurate or smooth.

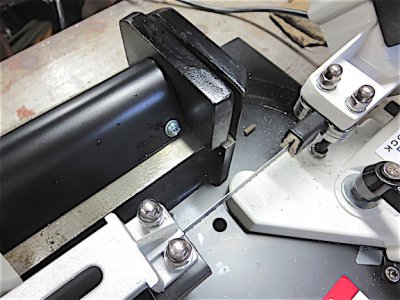

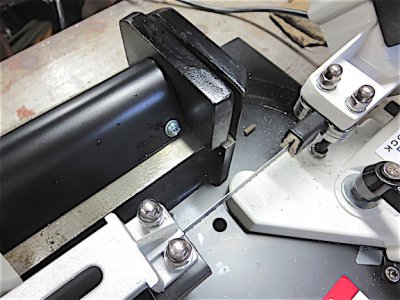

Northern Tools put this new saw on sale this month for $229. I had a $20 off coupon so the time seemed right. I'm very pleased with the quality of this little saw. It cuts very smoothly and the pivot bearing is pretty solid. It has a very nice and solid clamping vise. My only nit-pick is that the vise is too far from the blade. That should be easy enough to remedy with some jaw inserts, though a test cut on some 3/16" steel rod produced a very good result without much diflection.

It uses a geared motor, so it is a little noisy, but not nearly as loud as a circular saw.

Klutch Benchtop variable speed Metal Band Saw — 3in. x 4in.

Northern Tools put this new saw on sale this month for $229. I had a $20 off coupon so the time seemed right. I'm very pleased with the quality of this little saw. It cuts very smoothly and the pivot bearing is pretty solid. It has a very nice and solid clamping vise. My only nit-pick is that the vise is too far from the blade. That should be easy enough to remedy with some jaw inserts, though a test cut on some 3/16" steel rod produced a very good result without much diflection.

It uses a geared motor, so it is a little noisy, but not nearly as loud as a circular saw.

Klutch Benchtop variable speed Metal Band Saw — 3in. x 4in.

- Joined

- Feb 17, 2013

- Messages

- 4,406

Hmmmm ... I wonder if your laser has the power to burn paint off metal surfaces, or dark anodizing off aluminum. If so, you can make some very nice looking metal labels, etc.This one has a 2.5W laser and around an A3 operating envelope.

2.5W should allow me to engraver (well burn) wood and plastic and cut paper, foam and leather. Wont do anything to metal - you need to go to 50W CO2 lasers for that sort of thing, But I do hope to have some nice tool control foam inserts for my cabinet drawers in the my near future.

Nice looking kit!

T

TOOLMASTER

Forum Guest

Register Today

- Joined

- Feb 8, 2014

- Messages

- 11,144

T

TOOLMASTER

Forum Guest

Register Today

- Joined

- Mar 14, 2013

- Messages

- 443

The propeller spinner (nose cone) on my plane had cracked (again), so it was time to do something about it. It's spun aluminum, originally about 6 1/2" diameter. The first time it cracked, I stop drilled the crack and riveted a reinforcing plate inside, with another identical plate on the other side for balance. The second time it cracked, I decided to take a different approach, since I figured it would keep on cracking around the prop blade cutouts.

The spinner was originally sold as a "skull cap" spinner, intended to mount in front of a [larger] prop, without cutouts, but the previous owner had modified it to fit over the prop with the cutouts. Anyway, I figured I'd convert it back to a smaller skull cap.

The first challenge was to cleanly and accurately cut it. This project provided the justification to finally buy a rotary table, so I did (a 6" Accura/Vertex). I first bolted a piece of plywood to the table, routed a circular groove in it, and epoxied the spinner into the groove. I then used an .020 slitting saw (jewler's saw) to cut the spinner in half. As the cut proceeded, I used hot melt glue to hold it in place:

Next, I had to make a new backplate. I don't own a lathe or even a boring bar, so the rotary table would have to serve. I first xy'd the six mounting holes in both the new plate as well as a 1/2" thick tooling plate. With the backplate bolted to the tooling plate and indicated in, I first cut the outer circle, then machined it to the proper diameter with a step to receive the spinner, which I finished with a 60° countersink tool to match the spinner shape.

I then had to rework the center boss to a shorter length (again, no lathe, so I clamped the boss in the vise, indicated it, and drilled and tapped it. Here's what all the pieces looked like when finished:

And finally, what it looks like on a spare prop (I won't get to the airport to mount it on the plane until next week, I need to get a new center screw, too):

The spinner was originally sold as a "skull cap" spinner, intended to mount in front of a [larger] prop, without cutouts, but the previous owner had modified it to fit over the prop with the cutouts. Anyway, I figured I'd convert it back to a smaller skull cap.

The first challenge was to cleanly and accurately cut it. This project provided the justification to finally buy a rotary table, so I did (a 6" Accura/Vertex). I first bolted a piece of plywood to the table, routed a circular groove in it, and epoxied the spinner into the groove. I then used an .020 slitting saw (jewler's saw) to cut the spinner in half. As the cut proceeded, I used hot melt glue to hold it in place:

Next, I had to make a new backplate. I don't own a lathe or even a boring bar, so the rotary table would have to serve. I first xy'd the six mounting holes in both the new plate as well as a 1/2" thick tooling plate. With the backplate bolted to the tooling plate and indicated in, I first cut the outer circle, then machined it to the proper diameter with a step to receive the spinner, which I finished with a 60° countersink tool to match the spinner shape.

I then had to rework the center boss to a shorter length (again, no lathe, so I clamped the boss in the vise, indicated it, and drilled and tapped it. Here's what all the pieces looked like when finished:

And finally, what it looks like on a spare prop (I won't get to the airport to mount it on the plane until next week, I need to get a new center screw, too):

Made a cylindrical square on the new lathe to test out the headstock alignment. Came out damn near perfect. Couldn't measure any inconsistency in the diameter with two different mics. Big improvement over the old chattering Atlas 12".

Sent from my Nexus 6 using Tapatalk

Sent from my Nexus 6 using Tapatalk

Sent from my Nexus 6 using Tapatalk

Sent from my Nexus 6 using Tapatalk