- Joined

- Apr 23, 2018

- Messages

- 7,051

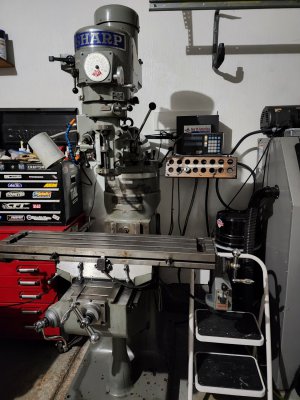

You can do it with nothing but an indicator mounted in the spindle with some offset. I was given one of those Edge tramming tools by my dad with the two indicators, and it makes the job a little bit easier, but it isn't necessary. Just sweep a circle on your table with the indicator and adjust the head accordingly. You can check for squaring in the same setup, indicator in the spindle. Then mount and square your vise. If your vise jaws aren't perfectly flat, you can clamp up a parallel or a 1-2-3 block in the vise and test off of that. If you get varying readings you are unhappy with, it's most likely loose gibs. Adjust those so they don't bind at the extreme ends of travel (that's where there's the least wear) and still a little bit of friction where you'll be working. The other adjustment is the lead screw nuts, same thing about wear being highest in the middle and splitting the difference between acceptable movement at the extremes. Don't kill yourself over lead screw backlash, though, it's not a big deal in practice. .025 is perfectly acceptable.Thank you, sir I truly believe so. As far as setting up the machine for squareness what tramming device would everyone recommend?

Edit- I know you have a Sharp, so try to get a Sharp manual (maybe Ozark Tool has one, or H&W Machine). If you can't, you can still glean the operation basics from a Bridgeport manual, which you can get free from Keith Rucker's vintagemachinery.org site/