-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turning a taper, which is the prefered method?

- Thread starter HRgx

- Start date

R

Robert LaLonde

Forum Guest

Register Today

Ray, thanks for driving the point home, it would simply be very poor practice to attempt to turn a long slow taper like that using a conventional tool without some sort of extra rest to support the work. However, this style of tool might be a hedge against the work jumping on top of the cutter.

http://gadgetbuilder.com/VerticalShearBit.html

Do you have any experience with this particular approach?

I just used a hand ground vertical shear yesterday to take the finish pass on a 10" long 416 tapered shaft. It works ok, but I found slow rpm, slow feed, small depth of cut. Just a couple thousandths. Its really only good in my opinion for finish cuts.

Its not hard to grind. Just give it a little relief angle behind the edge. Stone the edge to make it as sharp as its possible to make.

A vertical shear will even make the finish on low C steel "better." Better being a relative term.

I wonder if a tangential tool cutter would help with any chatter issues?

That is what gave me the best results so far in the test piece. The tangential bit has positive top rake and is easy to keep sharp. This was not on a full length barrel (see pics above) but I plan to try it when the time comes.

Last edited:

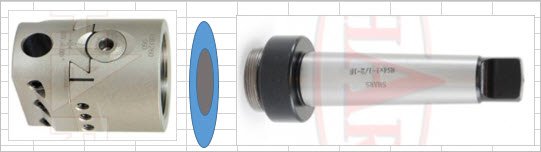

The MT3 arbor is tangless. At first I had the same question and made a sleeve to lock the boring head to the quill. After some tests it did not seem to be a problem. The MT3 taper holds very well on its own and was actually very difficult to eject from the quill. ... A more obscure cconcern is the boring head unscrewing on its arbor. A set screw was added on mine as can be seen in the first picture above.

I'm getting ready to pull the trigger on this hardware. I got thinking about the MT3 arbor again. Maybe a tang type would be a beneficial thing over tang-less. If it engages tailstock as its intended, then the only remaining problem is reliably orientating the boring head so it its extending horizontal. But I'm wondering if that would just be a matter of appropriate shim washer between the head & arbor. Once you figured out the correct thickness, it would be permanent & hopefully every time you re-installed into tailstock it would be the same, no?

Also, wouldn't normal chuck direction serve to be tightening the boring head threads vs. loosening?

** oh wait, are they reverse threads ? **

Another question, I envision making a 60-deg dead center from 0.5" stock (or whatever matches the appropriate boring head tool shank). What is the miracle grease people recommend for dead center friction work like this?

I looked for something that would be a mini live center with straight shank (vs dead center) & don't think it exists. Taking apart or otherwise trying to turn down a stock taper shank seems like a PITA although the one fellow did exactly that on YouTube vid. Any other ideas?

In my tailstock there is nothing for the tang to engage. Even if there was, my tests convinced me that the normal traction of a good MT taper is more than adequate. I prefer the simplicity of using a line level on the boring head to get it level then tap it into the quill until it is seated. Periodic checks with the level during my test runs did not show any movement whatsoever.

There is one surefire way to back up the MT taper and that is to put a clamp on the nose of the quill once the taper is set normally. See the third pic below.

With the muzzle end of the barrel at the tail stock, the boring head is set out towards the operator. Cutting forces tend to lift the barrel which puts a slight torque counter clockwise on the boring head. With vibration and time however it is enough to work the head loose on its threads if there is no locking mechanism. They are right hand threads. It obviously it takes much less torque to unscrew the boring head than it does to slip the MT taper. Even the slightest rotation of the boring head would have a drastic consequence on the cutting action.

When working between centers it is important to account for any heat build up in the barrel. This heating will expand the barrel and the centers will become too tight, possibly to the point of bowing the barrel. If this is left unattended there is no quality of grease that will work on centers that are binding.

I have been using quality white grease formulated for bicycle wheel bearings on a ball centre in the boring head. 60 deg pointed centers would have a harder time of it because they do not work as well at a slant. That is the reason I use a ball centre for turning tapers. Maybe someone else has a grease to recommend but there is no guarantee that it will work as well when the a pointed centre is set at an angle.

I have never seen a small enough live centre that could be used in a boring head whereas making up a couple of ball centers would be fairly straightforward. Please ask if would like to know more about making some.

There is one surefire way to back up the MT taper and that is to put a clamp on the nose of the quill once the taper is set normally. See the third pic below.

With the muzzle end of the barrel at the tail stock, the boring head is set out towards the operator. Cutting forces tend to lift the barrel which puts a slight torque counter clockwise on the boring head. With vibration and time however it is enough to work the head loose on its threads if there is no locking mechanism. They are right hand threads. It obviously it takes much less torque to unscrew the boring head than it does to slip the MT taper. Even the slightest rotation of the boring head would have a drastic consequence on the cutting action.

When working between centers it is important to account for any heat build up in the barrel. This heating will expand the barrel and the centers will become too tight, possibly to the point of bowing the barrel. If this is left unattended there is no quality of grease that will work on centers that are binding.

I have been using quality white grease formulated for bicycle wheel bearings on a ball centre in the boring head. 60 deg pointed centers would have a harder time of it because they do not work as well at a slant. That is the reason I use a ball centre for turning tapers. Maybe someone else has a grease to recommend but there is no guarantee that it will work as well when the a pointed centre is set at an angle.

I have never seen a small enough live centre that could be used in a boring head whereas making up a couple of ball centers would be fairly straightforward. Please ask if would like to know more about making some.

Last edited:

Very good info Tozguy, thanks.

- I'm still not comprehending the clamp pic, they look like they are on the tailstock barrel. isntthe unscrewing issue between the boring head & threaded arbor? (red arrow)

I like that bearing ball concept. II have a model engineering book (George Thomas?) where he describes exactly that. there is a relationship to ball size & 60-deg center depth, but that would appear to take care of hardness & the swivel+rotation movement simultaneously.

- How did you retain the ball (like locktite, silver solder...0 and what kin dof divot is on the backside that it engages in?

- do you have a series of ball centers like at progressive diameters?

- out of interest, did you ever try those special elliptical center drills (or whatever the curve profile is) specifically intended to work with conventional 60-deg dead centers?

If I was choosing between 2" or 3" boring head, any pros & cons you can think of? 3" is a bit more beefy, sticks out further has slightly more deflection range but guessing either should satisfy most typical arbor tapers I'm doing. 3" uses larger tools, 2" is I believe 0.5" shank. Do you find you can get to your carriage dials ok under the head or do you have to keep the compound at a certain position?

- I'm still not comprehending the clamp pic, they look like they are on the tailstock barrel. isntthe unscrewing issue between the boring head & threaded arbor? (red arrow)

I like that bearing ball concept. II have a model engineering book (George Thomas?) where he describes exactly that. there is a relationship to ball size & 60-deg center depth, but that would appear to take care of hardness & the swivel+rotation movement simultaneously.

- How did you retain the ball (like locktite, silver solder...0 and what kin dof divot is on the backside that it engages in?

- do you have a series of ball centers like at progressive diameters?

- out of interest, did you ever try those special elliptical center drills (or whatever the curve profile is) specifically intended to work with conventional 60-deg dead centers?

If I was choosing between 2" or 3" boring head, any pros & cons you can think of? 3" is a bit more beefy, sticks out further has slightly more deflection range but guessing either should satisfy most typical arbor tapers I'm doing. 3" uses larger tools, 2" is I believe 0.5" shank. Do you find you can get to your carriage dials ok under the head or do you have to keep the compound at a certain position?

The collar clamp I referred to is the one closest to the boring head. It is on the nose of the quill. It provides extra hold on the MT3 taper by compressing the front of the MT3 socket after the arbor is put in place. It does not secure the boring head on its arbor in any way. The other clamp to the right is mounted on the tail stock body and is used to prevent the quill from moving. For normal operation it is left loose so the quill slides in and out of the TS with no binding.

The unscrewing issue was solved by drilling and tapping the boring head for a set screw into the middle of the threads. Visible in the pictures.

A 5/16'' ball was used for 6mm bores and a 3/8'' ball for 30 cal. bores. The sockets (divots) for the ball were cut round to hold exactly 1/2 of the ball. I had a 5/16 round Dremel cutter on hand but I had to buy a 3/8 cutter for the larger ball. The balls were glued in with liquid Krazy glue. There is a slight cone cut on the shoulder surrounding the ball to provide relief for the barrel.

The size of the balls was limited somewhat by what cutters are readily available.The balls have to be bigger than the bore but not too big.

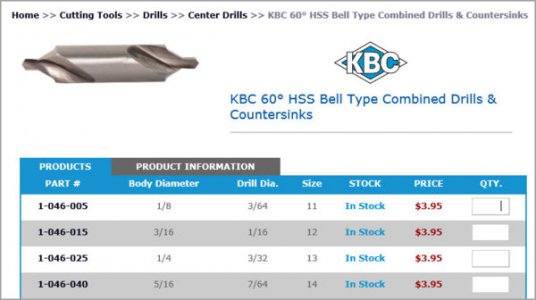

To get a 60 deg contact ring on a ball just chamfer the bore slightly with a centre drill. For example, a 5/16 (.3125'') ball inserted in a 60 deg centre divot will have a contact ring .270''in diameter. So a .243'' bore would have to be chamfered out to at least .270'' to get a good fit.

I am not familiar with special elliptical centre drills, what is special about them?

I chose a 2'' boring head with 1/2'' holes because I already have 1/2'' shank boring bars, they have sufficient adjustment range and they were on special at BB. There has been no special clearance issues when using this set up.

I hope i understood your questions properly.

The unscrewing issue was solved by drilling and tapping the boring head for a set screw into the middle of the threads. Visible in the pictures.

A 5/16'' ball was used for 6mm bores and a 3/8'' ball for 30 cal. bores. The sockets (divots) for the ball were cut round to hold exactly 1/2 of the ball. I had a 5/16 round Dremel cutter on hand but I had to buy a 3/8 cutter for the larger ball. The balls were glued in with liquid Krazy glue. There is a slight cone cut on the shoulder surrounding the ball to provide relief for the barrel.

The size of the balls was limited somewhat by what cutters are readily available.The balls have to be bigger than the bore but not too big.

To get a 60 deg contact ring on a ball just chamfer the bore slightly with a centre drill. For example, a 5/16 (.3125'') ball inserted in a 60 deg centre divot will have a contact ring .270''in diameter. So a .243'' bore would have to be chamfered out to at least .270'' to get a good fit.

I am not familiar with special elliptical centre drills, what is special about them?

I chose a 2'' boring head with 1/2'' holes because I already have 1/2'' shank boring bars, they have sufficient adjustment range and they were on special at BB. There has been no special clearance issues when using this set up.

I hope i understood your questions properly.

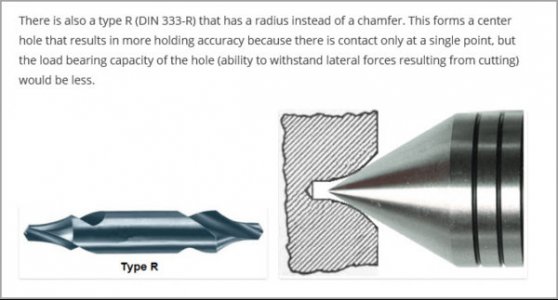

I’m no expert but I think the way they are supposed to work is same principle as your ball end dead center. In conventional turning, a 60-deg dead center point exactly aligns to 60-deg center drill hole. Now when you offset the work for taper turning, it’s no longer aligned & coincident cone within a cone. The dead center can only partially contacting an edge of the angled part. I think a curved center drill profile is intending to provide better contact to linear 60-deg center tip, which remains aligned parallel to bed axis. But I’m still fuzzy as to how much more contact, or if the objective is more-so to get contact it inside the cone as opposed to the lip? I can visualize a ball though, its spherically curved so it has to be making a full circle contact line and inside even a conventional 60-deg center drill profile. Then again the cutting force is only pushing on one side of the center drill / support. The book I have draws this out, I’ll have to take a peek again.

Last edited: